Submit feedback

Pneumatic Industrial Fans: A High-Efficiency and Low-Cost Option for Industrial Ventilation Systems

2025.09.15

2025.09.15

Industry News

Industry News

In modern industry, pneumatic industrial fans have become indispensable equipment in many sectors due to their high efficiency and wide range of applications. Whether in mining, chemical manufacturing, metallurgy, or environmental protection, ventilation, or air purification, pneumatic fans play a vital role.

How Pneumatic Industrial Fans Work

Pneumatic industrial fans are gas-powered fans. Unlike traditional electric fans, pneumatic fans use compressed air as a power source to rotate the fan impeller, thereby creating air flow. These fans are often used in applications requiring high pressure, high flow, or specialized gas environments. They offer an ideal alternative, particularly in locations where electrical equipment is unavailable or presents safety risks.

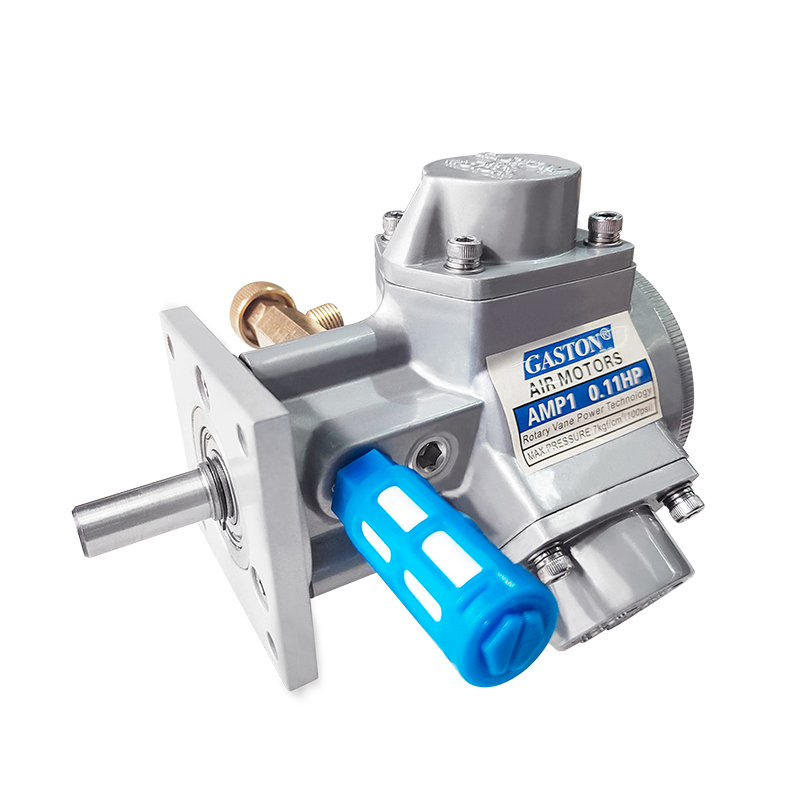

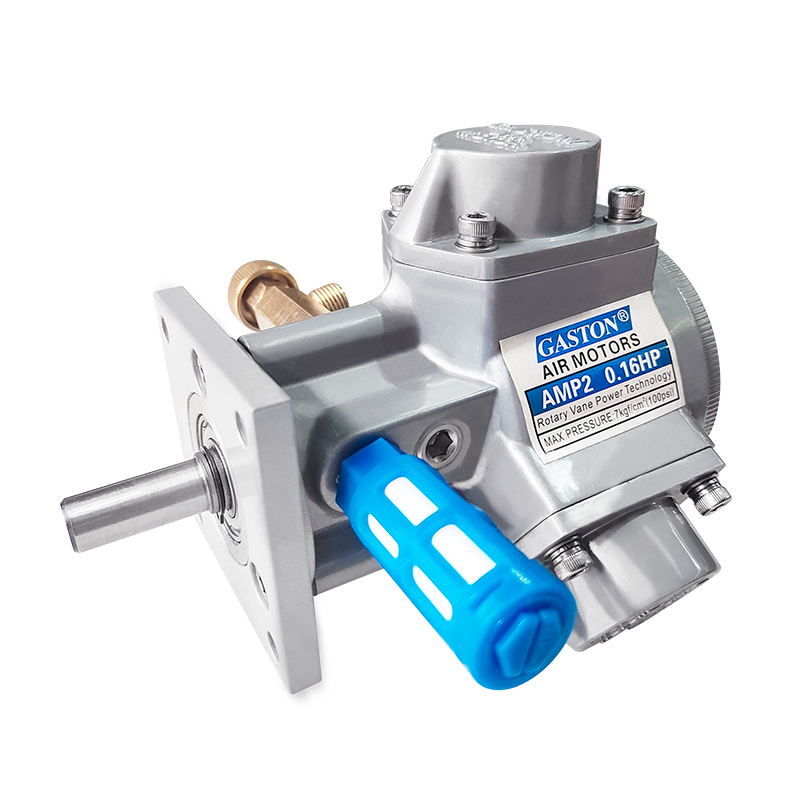

The core components of a pneumatic fan include a compressed air supply system, an air motor, a fan impeller, and an exhaust system. Compressed air enters the fan through the air motor, where the motor's rotation drives the fan impeller, generating airflow. Unlike traditional electric fans, pneumatic fans do not generate electromagnetic interference during operation, making them suitable for use in environments with strict electromagnetic requirements.

Applications of Pneumatic Industrial Fans

Due to their unique operating principles and advantages, pneumatic industrial fans are widely used in various industries.

Mining and Metallurgical Industries

Mine ventilation is crucial during mining operations. Pneumatic fans have strong explosion resistance, making them suitable for use in flammable and explosive environments, ensuring the safety of miners at work. Their high-pressure performance enables them to effectively pump air deep underground, ensuring air circulation inside and outside mines.

The metallurgical industry also requires powerful ventilation systems, especially in high-temperature and high-pressure environments. The stability and high-temperature resistance of pneumatic fans make them an ideal choice. Pneumatic fans not only provide efficient airflow but also operate stably in high-temperature and high-humidity environments, such as those found in metallurgical plants.

Chemical and Pharmaceutical Industries

Pneumatic fans are also widely used in the chemical and pharmaceutical industries. These industries often involve toxic and volatile gases in their production processes. Pneumatic fans utilize compressed air instead of electricity, reducing safety hazards caused by sparks from electrical equipment. In these areas, pneumatic fans are also frequently used for exhaust gas removal, gas purification, and material conveying.

Environmental Protection and Ventilation

Pneumatic fans play a vital role in environmental protection industries, such as air purification and exhaust gas treatment. They efficiently exhaust harmful gases, smoke, and dust, reducing environmental pollution. In some urban construction projects, pneumatic fans are also commonly used in underground duct ventilation systems to ensure smooth air circulation.

Advantages of Pneumatic Industrial Fans

Pneumatic industrial fans have become the preferred equipment in many industrial sectors due to their many unique advantages.

Efficient and Stable Performance

Because pneumatic fans use compressed air as their power source, they offer higher power density and flow capacity. Compared to traditional electric fans, pneumatic fans can operate at higher pressures and maintain a more stable airflow. Even in complex and harsh environments, pneumatic fans provide long-term, stable operation, reducing the risk of equipment failure. High Safety

Pneumatic fans are powered by compressed air, eliminating the electrical faults and sparks common with electric fans. Therefore, they are suitable for use in flammable and explosive environments and offer a high level of safety. For example, pneumatic fans are widely used in specialized locations such as chemical plants and oil drilling platforms, effectively avoiding the risk of fire and explosion caused by electrical equipment.

Environmental Protection and Energy Saving

Pneumatic fans are powered by compressed air, which not only reduces energy consumption during operation but also has a minimal environmental impact. In industries that handle pollutants such as dust and smoke, pneumatic fans can effectively remove harmful substances from the environment, achieving air purification and meeting current environmental protection requirements.

Low Maintenance Cost

Pneumatic fans have a simpler structure, eliminating the need to worry about motor burnout during maintenance. Compared to traditional electric fans, pneumatic fans have lower maintenance costs. Because the compressed air drive system is inherently less susceptible to electrical faults, it has a longer service life. Regular inspection and cleaning can ensure long-term, efficient operation.

Pneumatic industrial fans, with their high efficiency, stability, and safety, have become indispensable equipment in various industrial sectors. Whether in mining, metallurgy, chemical industry, or environmental ventilation, pneumatic fans play a huge role. In the future, with the continuous advancement of technology, the application prospects of pneumatic fans will be even broader, becoming an important part of industrial automation and intelligentization.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى