Submit feedback

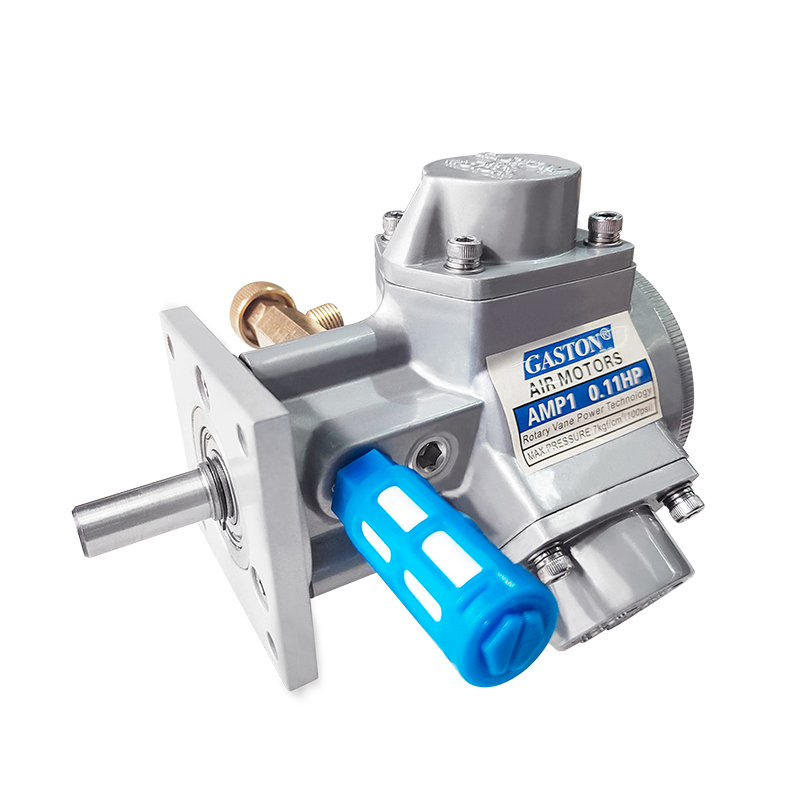

Stainless Steel Pneumatic Pumps: An Ideal Choice for Industrial Applications

2025.09.22

2025.09.22

Industry News

Industry News

With the advancement of industrial automation technology, pneumatic pumps, as an efficient and reliable fluid transport tool, are increasingly being used across various industries. Stainless Steel Pneumatic Pumps, in particular, have become the preferred choice in many demanding industries due to their excellent corrosion resistance, high temperature resistance, and durability.

How Stainless Steel Pneumatic Pumps Work

Stainless steel pneumatic pumps are fluid transport devices powered by compressed air. Their core principle is that compressed air propels a piston or diaphragm, thereby drawing and discharging fluid. Compressed air flows through the air valve control system within the pump body, creating a pressure differential within the pump, which propels the piston or diaphragm, causing the fluid to flow alternately between the two working chambers. This design allows stainless steel pneumatic pumps to operate without requiring a power source, making them suitable for many applications requiring efficient fluid transport.

Advantages of Stainless Steel Pneumatic Pumps

1. Excellent Corrosion Resistance

Stainless steel, as an extremely corrosion-resistant material, is widely used in the chemical, food, and pharmaceutical industries, particularly when handling corrosive fluids, effectively preventing equipment damage caused by metal corrosion. Stainless steel pneumatic pumps excel in these industries precisely because of these advantages. Whether handling acidic, alkaline, or other highly corrosive liquids, stainless steel pneumatic pumps ensure long-term, stable operation.

2. Reliable High-Temperature Tolerance

Stainless steel has a higher melting point and high-temperature resistance, making stainless steel pneumatic pumps more reliable than standard plastic or aluminum pumps when handling high-temperature fluids. For specialized industrial processes, such as hot oil transfer and high-temperature chemical liquids, stainless steel pneumatic pumps can continue to operate stably in extreme temperatures, ensuring long life and high efficiency.

3. Simple Maintenance and Long Service Life

Stainless steel pneumatic pumps feature a simple design and require no electrical power, reducing the risk of electrical failure. Their durable materials and simple construction also make maintenance easier. Regular inspection and replacement of a small number of wearing parts can extend the pump's service life to over ten years. Because their built-in air drive system reduces reliance on electricity, the pump's reliability and safety are significantly enhanced.

Applications of Stainless Steel Pneumatic Pumps

Stainless steel pneumatic pumps are widely used in various industries:

1. Chemical Industry

In the chemical industry, many liquids are highly corrosive or flammable, and conventional pumps may not be able to meet these requirements. Using stainless steel pneumatic pumps not only effectively avoids these problems but also maintains stability in high-temperature and high-pressure environments. Whether it's acidic or alkaline solutions or organic solvents, stainless steel pneumatic pumps can efficiently and safely transport these hazardous chemicals.

2. Food and Pharmaceutical Industry

The food and pharmaceutical industries have very high requirements for equipment hygiene. Stainless steel, as a non-toxic, odorless, and easy-to-clean material, is an ideal choice for this industry. Stainless steel pneumatic pumps are widely used in this field to transport various liquids, such as food additives and pharmaceutical solutions. Their hygienic and pollution-free properties ensure product safety and quality.

3. Oil and Gas Industry

In the oil and gas industry, fluidity and flow control are crucial. Especially when transporting high-viscosity liquids during drilling and extraction processes, stainless steel pneumatic pumps, with their high performance and excellent wear resistance, are essential tools in this industry. Whether conveying petroleum, lubricants, or other high-viscosity liquids, stainless steel pneumatic pumps provide continuous and stable flow.

4. Environmental Protection Industry

Many fluid handling processes within the environmental protection industry, such as sewage treatment and wastewater recycling, often require efficient fluid conveying equipment. Stainless steel pneumatic pumps, due to their excellent corrosion resistance, can operate for extended periods in these harsh environments, ensuring effective fluid delivery and improving the overall operational efficiency of environmental protection facilities.

Selecting and Maintaining Stainless Steel Pneumatic Pumps

When selecting a stainless steel pneumatic pump, the first consideration is the properties of the working fluid. Different liquids require different pump material qualities, so the appropriate grade of stainless steel should be selected based on the specific application. Secondly, technical parameters such as flow rate and pressure should be considered to ensure the pump can meet the required workload. Finally, regular maintenance and inspection are key to ensuring the pump's long-term and efficient operation, especially the regular replacement of vulnerable components such as valves and seals.

As an efficient, durable, and environmentally friendly fluid conveying tool, stainless steel pneumatic pumps are increasingly used across various industries. Their excellent corrosion resistance, high-temperature tolerance, and long service life make them indispensable equipment in many industrial fields. With the continuous development of technology and the expansion of application fields, stainless steel pneumatic pumps will provide more reliable solutions for more industries and promote the continuous improvement of industrial automation levels.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى