Submit feedback

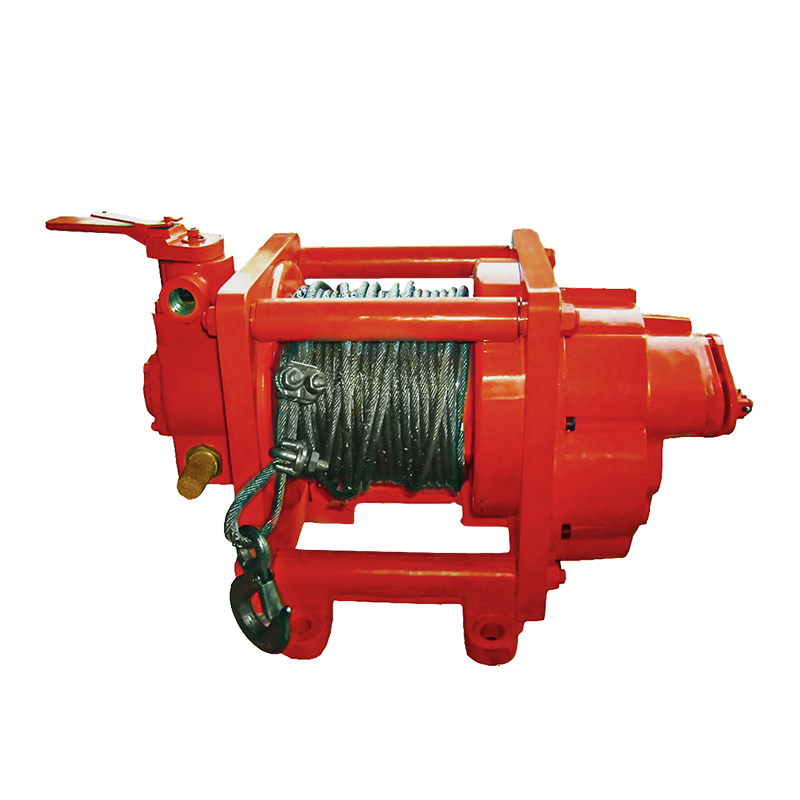

HQ Gaston mining pneumatic hoist

HQ Gaston Mining Pneumatic Hoist is a high-efficiency, high-reliability lifting equipment specially designed for the mining environment. With its unique pneumatic drive system, it can still operate stably in harsh mining environments, ensuring the safety and efficiency of miners' operations. Using advanced pneumatic technology, no electric drive is required, which reduces safety hazards caused by unstable power and reduces maintenance costs. Designed with high-strength alloy chains and a solid lifting frame, it ensures stable operation under heavy load conditions and meets the load-bearing requirements of mining operations. After special dust-proof, waterproof, and anti-corrosion treatment, it can work for a long time in humid, dusty, and highly corrosive mining environments. HQ Gaston mining pneumatic hoists are widely used in various mining operation scenarios, such as coal mining, metal ore extraction, tunnel construction, etc. It can easily cope with complex operating environments and provide strong lifting support for mining production.

-

DETAIL PARAMETERS

Performance characteristics of air hoist

|

Air pressure (PSI) |

Air pressure (Mpa) |

Maximum Power (HP) | Free speed (rpm) | Speed at maximum power (rpm) | Torque at maximum power (NM) | Air consumption at maximum power (m3/min) | Stop torque and start torque (NM) |

| 40 | 0.28 | 45% | 80% | 30% | 37.50% | 45% | 45% |

| 50 | 0.35 | 56% | 84% | 44% | 52.40% | 56% | 56% |

| 60 | 0.4 | 67% | 88% | 58% | 65.90% | 67% | 67% |

| 70 | 0.48 | 78% | 92% | 72% | 78.30% | 78% | 78% |

| 80 | 0.55 | 89% | 96% | 86% | 89.60% | 89% | 89% |

| 90 | 0.63 | 100% | 100% | 100% | 100% | 100% | 100% |

| 100 | 0.7 | 110% | 104% | 114% | 109.60% | 110% | 110% |

|

|

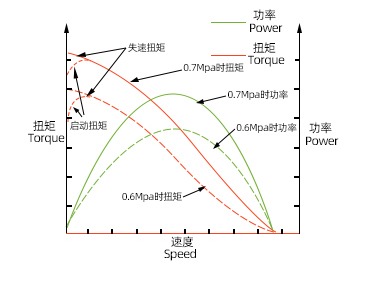

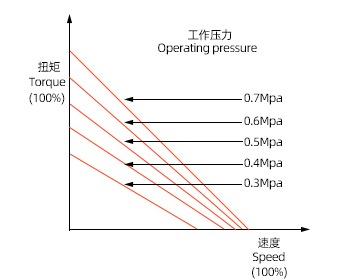

| The figure shows a typical pneumatic motor torque and power curve at two different air pressures. The motor speed, torque and power decrease as the air pressure decreases. | The figure shows the torque and speed curves of the pneumatic motor under two different air pressures. The speed and torque of the motor decrease as the air pressure decreases. The torque decreases significantly, while the motor speed decreases slightly as the pressure decreases. |

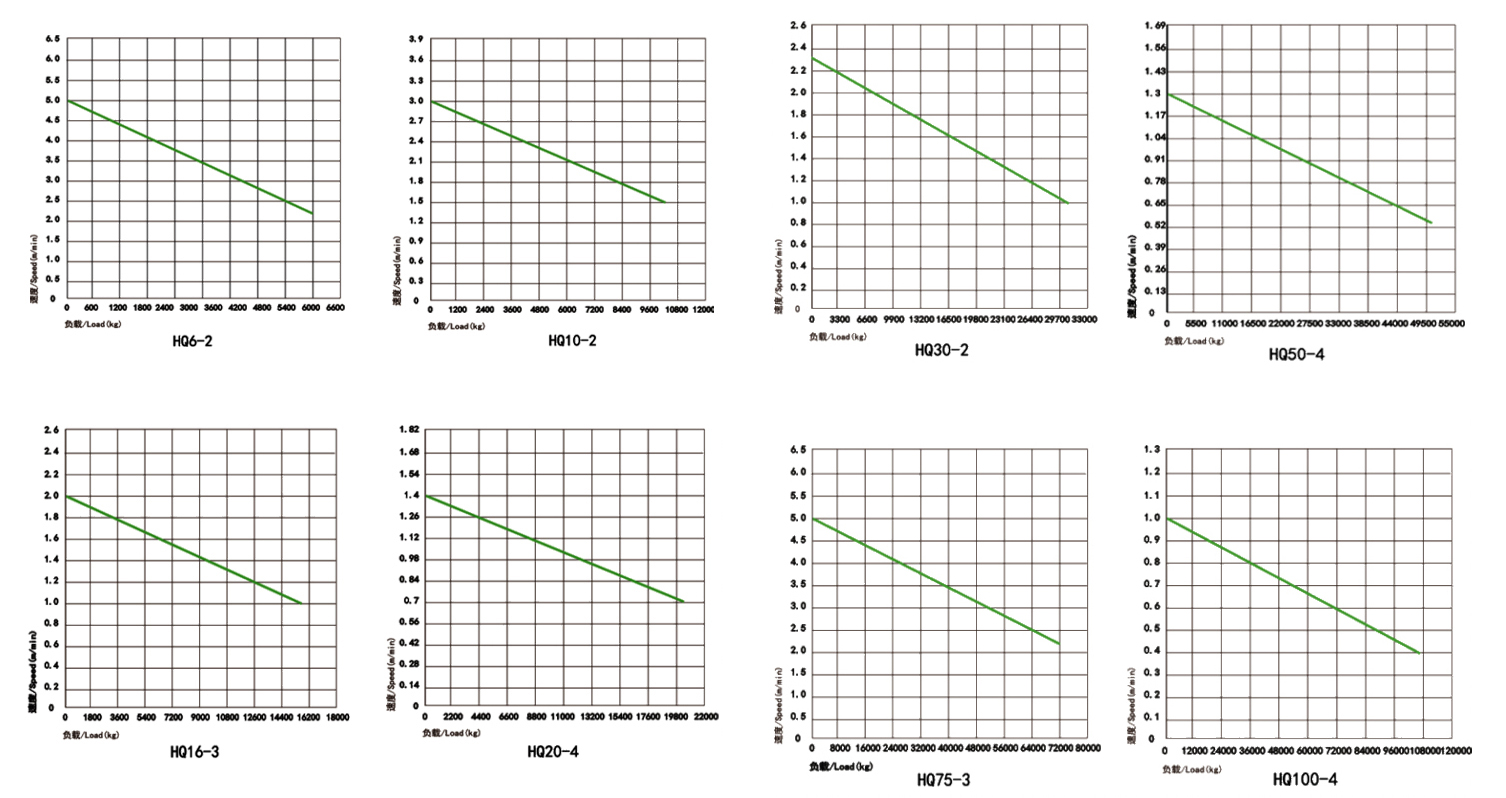

Performance curve graph

Technical Data Sheet

|

Mold |

Unit |

HQ16-3 |

HQ20-4 |

HQ30-2 |

HQ50-4 |

HQ75-3 |

HQ100-4 |

|

Air pressure |

Mpa |

0.6 |

|||||

|

Load |

(Tons) |

16 |

20 |

30 |

50 |

75 |

100 |

|

Number of chains |

root |

3 |

4 |

2 |

4 |

3 |

4 |

|

Motor output power |

(KW) |

3.5 |

3.5 |

6.3 |

6.3 |

9 |

9 |

|

Lifting height |

(m) |

The standard height is 3 meters |

|||||

|

Full load lifting speed |

(m/min) |

1 |

0.7 |

1 |

0.7 |

0.55 |

0.4 |

|

No-load lifting speed |

(m/min) |

2 |

1.4 |

2.3 |

1.2 |

1.3 |

1 |

|

Full load descent speed |

(m/min) |

1.6 |

1.6 |

2.8 |

1.5 |

1.2 |

1 |

|

Full load gas consumption - increased |

(m³/min) |

4 |

4 |

6.5 |

4 |

7.6 |

7.6 |

|

Full load gas consumption - down |

(m³/min) |

5.5 |

5.5 |

5.5 |

5.5 |

6 |

6 |

|

Chain size |

mm |

16*45 |

16*45 |

22*66 |

22*66 |

32*96 |

32*96 |

|

Chain weight |

kg/m |

3.8 |

3.8 |

11.8 |

11.8 |

22.5 |

22.5 |

|

Standard weight (3m lifting height) |

(kg) |

210 |

310 |

520 |

935 |

1750 |

1800 |

|

Controller air pipe length |

(m) |

Standard length is 3 meters |

|||||

|

Full load noise - increased |

(db) |

78 |

78 |

78 |

78 |

78 |

78 |

|

Full load noise - down |

(db) |

80 |

80 |

82 |

82 |

85 |

85 |

|

Trachea connector |

(in) |

G3/4 |

G3/4 |

G11/2 |

G11/2 |

G11/2 |

G11/2 |

|

Air pipe size (inner diameter) |

(mm) |

19 |

19 |

35 |

35 |

35 |

35 |

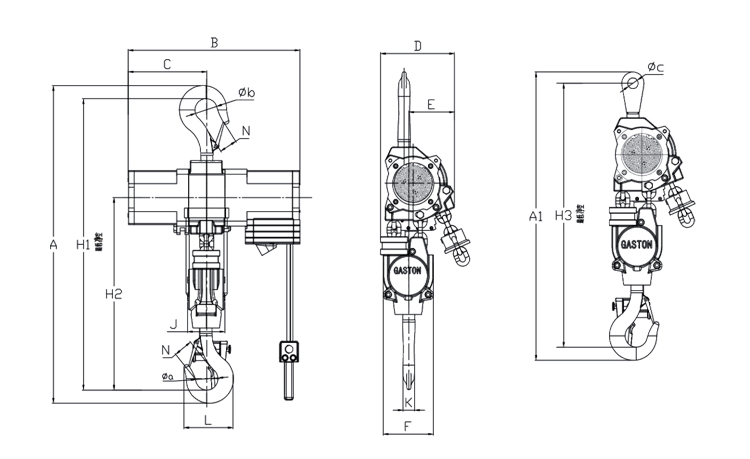

Dimensions

|

|

Dimensions

|

Model |

Unit |

HQ1.5-1 |

HQ2-2 |

HQ3-1 |

HQ3-2 |

HQ6-2 |

HQ10-2 |

|

A |

mm |

690 |

556 |

905 |

690 |

905 |

1050 |

|

A1 |

mm |

608 |

585 |

885 |

608 |

885 |

960 |

|

B |

mm |

436 |

35 |

539 |

436 |

539 |

558 |

|

C |

mm |

202 |

146 |

246.5 |

202 |

246.5 |

256 |

|

D |

mm |

176 |

185 |

220 |

176 |

220 |

256 |

|

E |

mm |

100 |

140 |

146 |

100 |

146 |

128 |

|

F |

mm |

150 |

385 |

158 |

150 |

158 |

205 |

|

J |

mm |

90 |

65 |

120 |

90 |

120 |

135 |

|

K |

mm |

26.5 |

26 |

38 |

26.5 |

38 |

49 |

|

H1 minimum clearance |

mm |

659 |

500 |

807 |

659 |

807 |

969 |

|

H2 |

mm |

439 |

338 |

548 |

439 |

548 |

652 |

|

H3 |

mm |

597 |

528 |

768 |

597 |

768 |

860 |

|

φa |

mm |

53 |

48 |

69 |

53 |

69 |

55 |

|

φb |

mm |

53 |

48 |

69 |

53 |

69 |

55 |

|

φc |

mm |

28 |

28 |

33 |

28 |

33 |

36 |

|

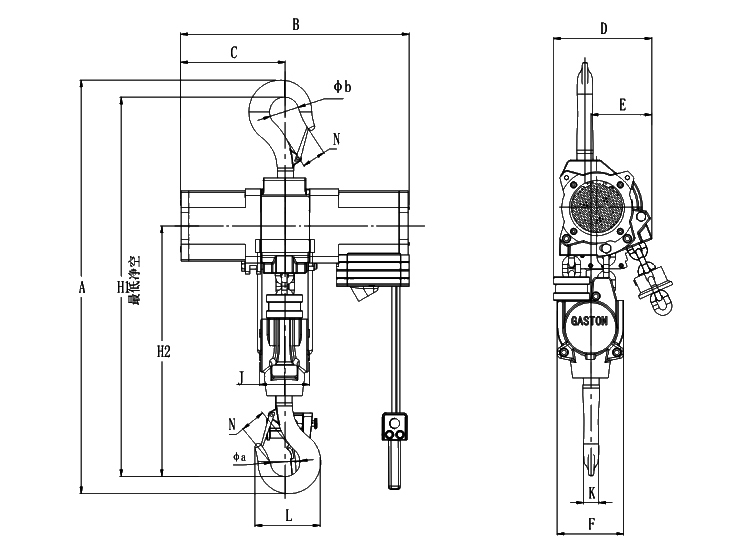

Model |

Unit |

HQ16-3 |

HQ20-4 |

HQ30-2 |

HQ50-4 |

HQ75-3 |

HQ100-4 |

|

A |

mm |

1350 |

1195 |

1370 |

1610 |

2535 |

2610 |

|

B |

mm |

558 |

559 |

900 |

955 |

1535 |

1535 |

|

C |

mm |

246.5 |

247 |

450 |

530 |

820 |

820 |

|

D |

mm |

386 |

472 |

445 |

445 |

600 |

600 |

|

E |

mm |

195 |

127 |

270 |

270 |

405 |

365 |

|

F |

mm |

262 |

365 |

310 |

350 |

450 |

450 |

|

H1 minimum clearance |

mm |

1163 |

1117 |

1260 |

1485 |

1935 |

1935 |

|

H2 |

mm |

675 |

630 |

825 |

950 |

1250 |

1250 |

|

φa |

mm |

95 |

102 |

126 |

120 |

315 |

355 |

|

φb |

mm |

95 |

102 |

126 |

120 |

315 |

355 |

|

N |

mm |

88 |

95 |

113 |

122 |

250 |

280 |

|

Pneumatic hoist |

HQ2-2 |

HQ3-2 |

HQ6-2 |

HQ10-2 |

HQ16-3 |

HQ20-4 |

|

Walking car |

QDC-2 |

QDC-3 |

QDC-6 |

QDC-10 |

QDC-16 |

QDC-20 |

|

A |

325 |

340 |

400 |

496 |

496 |

675 |

|

B |

125 |

140 |

155 |

186 |

186 |

270 |

|

b Running track width range |

80-120 |

110-150 |

200-250 |

200-250 |

200-250 |

250-300 |

|

bm |

168 |

235 |

330 |

350 |

375 |

375 |

|

C |

218 |

250 |

290 |

364 |

364 |

490 |

|

D |

110 |

120 |

135 |

166 |

166 |

240 |

|

E |

45 |

68 |

53 |

144 |

147 |

157 |

|

F |

210 |

290 |

322 |

358.5 |

358.5 |

313 |

|

G |

145 |

176 |

256 |

256 |

386 |

472 |

|

H Minimum clearance |

615 |

626 |

973 |

973 |

980 |

1270 |

|

h |

120 |

130 |

140 |

140 |

166 |

250 |

|

J |

90 |

93 |

118 |

135 |

200 |

120 |

|

K |

26 |

30 |

36 |

49 |

60 |

72 |

|

L |

169 |

232.5 |

293 |

303 |

295 |

293 |

|

M |

146 |

203.5 |

249 |

256 |

245 |

247 |

|

N |

33 |

35 |

48 |

66 |

88 |

95 |

|

P |

140 |

146 |

142.7 |

128 |

195 |

127 |

|

Φ |

48 |

53 |

69 |

71 |

95 |

102 |

About Us

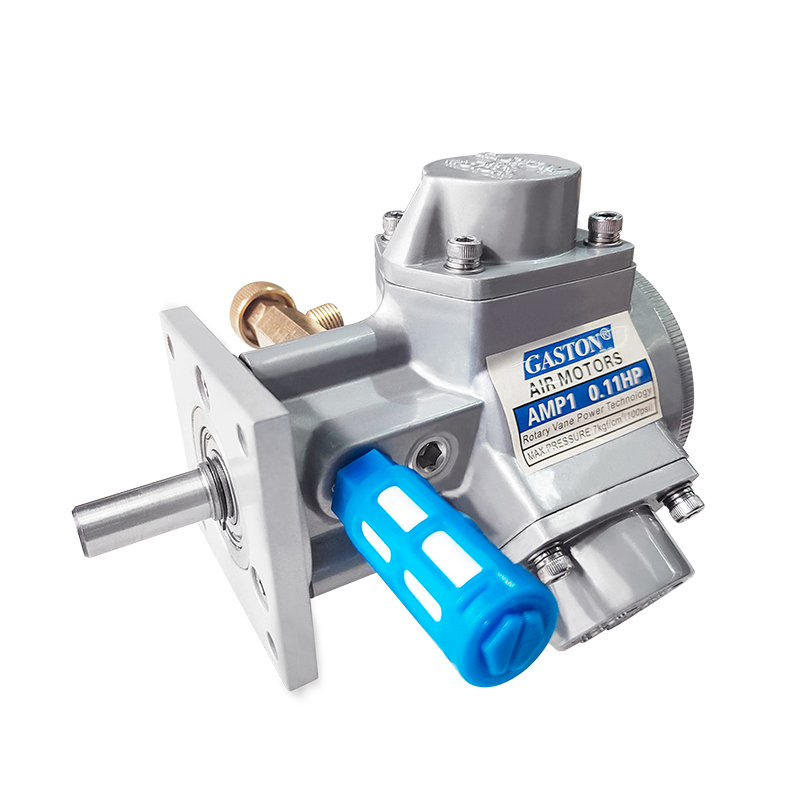

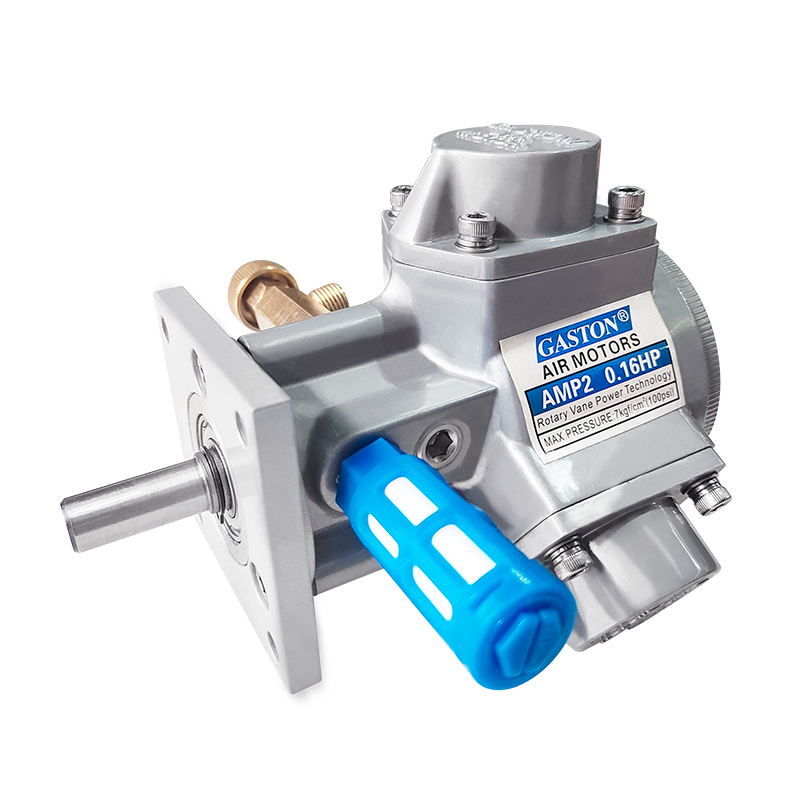

The company has been committed to product innovation for many years, focusing on the updating and upgrading of pneumatic motors. With fine concepts and continuous investment, it has created a creative design team and has designed multiple innovative pneumatic products. Currently, it has independent intellectual property rights and has obtained more than 30 product patents.

The company's main products include pneumatic motors and a series of products such as pneumatic hoists, pneumatic winches, pneumatic mixers, pneumatic emulsifiers, pneumatic explosion-proof pumps, pneumatic mixers, pneumatic fans, and industrial automation equipment pneumatic control system engineering developed based on specific production needs.

The company strictly follows the ISO9001 quality management system for product design, production, assembly, and testing. With the efforts of all employees, the company has passed the ISO9001 international quality system certification. Through strict procedures and high standards of auditing, the company has successfully passed the recognition of a "national high-tech enterprise". Gaston Company is gradually moving towards internationalization with its own strength and a global perspective.

Users with different needs will always be the coordinates we strive for and the driving force for constantly surpassing ourselves and striving for innovation! Gaston Company looks forward to sincere cooperation with friends from all walks of life at home and abroad to create brilliance together!

Latest News

-

Industry News 2025-09-22

With the advancement of industrial automation technology, pneumatic pumps, as an efficient and reliable fluid transport tool, are increasingly being used across various industries. Stainless Steel Pne...

View More -

Industry News 2025-09-15

In modern industry, pneumatic industrial fans have become indispensable equipment in many sectors due to their high efficiency and wide range of applications. Whether in mining, chemical manufacturing...

View More -

Industry News 2025-09-08

In modern industrial production systems, the performance of power units directly determines the efficiency and stability of production processes. As a drive device using compressed air as its core pow...

View More

KEEP IN TOUCH

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى