Submit feedback

Pneumatic Air Winch: A powerful assistant in the industrial field

2025.06.08

2025.06.08

Industry News

Industry News

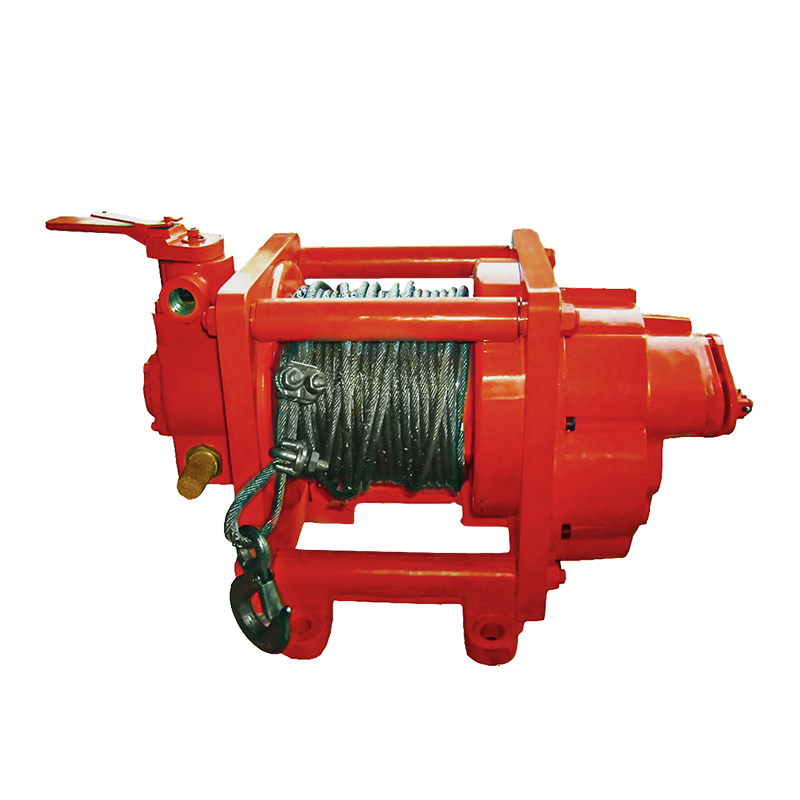

In many industrial scenarios, we often see a device that uses compressed air as a power source operating efficiently, which is the Pneumatic Air Winch. As a heavy-duty air-powered winch, the pneumatic winch performs well in lifting and pulling heavy objects and is favored by various industries.

1. The working principle is revealed

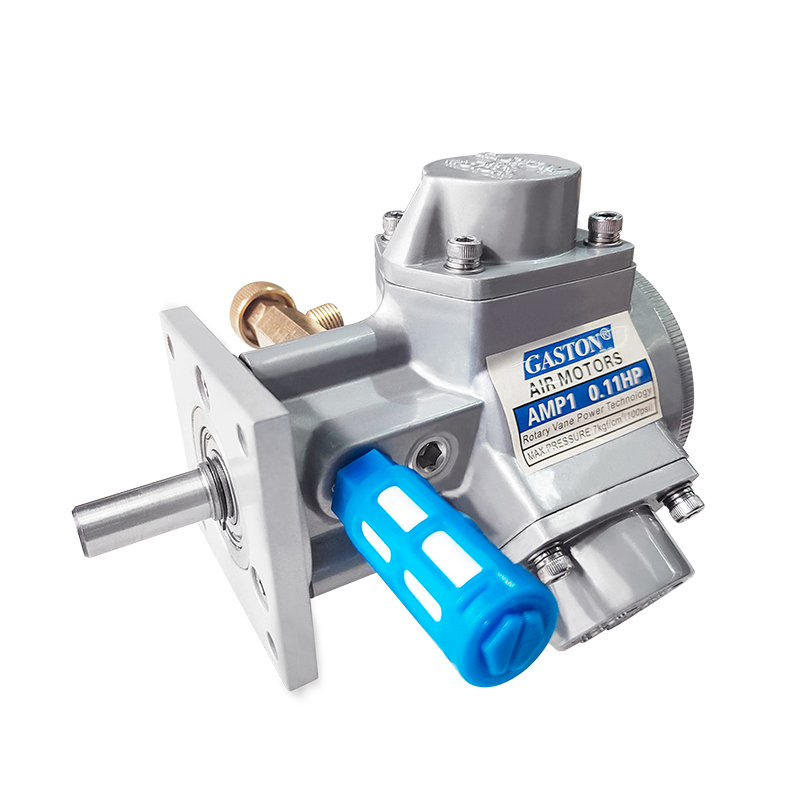

The pneumatic winch is mainly composed of pneumatic motors, reduction gear mechanisms, drums, brake systems and other parts. When compressed air enters the pneumatic motor, it will push the blades or pistons inside the motor to move, thereby generating rotational power. This power is transmitted to the drum through the reduction gear mechanism, allowing the drum to rotate forward or reverse at the set speed, thereby realizing the retraction and release of the rope, and completing the lifting, lowering or pulling of heavy objects. Taking the vane-type pneumatic motor as an example, after the compressed air enters the air chamber, it will push the blades to drive the rotor to rotate, and the whole process is efficient and stable.

II. Wide range of application areas

(I) Oil and gas industry

Whether it is the exploitation of onshore oil fields or the operation of offshore oil platforms, pneumatic winches play a key role. During the drilling process, it can be used to lift and lower heavy equipment such as drill pipes and casing to ensure the smooth progress of drilling operations. In the flammable and explosive natural gas mining environment, its explosion-proof characteristics are indispensable and can effectively ensure the safety of personnel and equipment.

(II) Mining field

In mining operations such as coal mines and metal mines, heavy objects such as ores and equipment need to be frequently moved. With its powerful traction and lifting capabilities, as well as good dust and water resistance, pneumatic winches can adapt to the harsh working environment in mines and provide reliable power support for mining.

(III) Shipbuilding and marine engineering

During the construction and maintenance of ships, pneumatic winches can be used to lift various parts and equipment. In the field of marine engineering, such as the installation of offshore wind power equipment, it can accurately lift large wind turbine components to the designated location, contributing to marine development.

III. Unique advantages show their charm

(I) Excellent explosion-proof performance

Compared with electric winches, pneumatic winches do not generate electric sparks during operation, which makes them the best choice in flammable and explosive environments and can greatly ensure the safety of personnel and property.

(II) Compact structure and easy installation

Its compact design takes up little space, making it easy to install and use in various workplaces with limited space, and it is extremely flexible.

(III) Smooth operation and easy operation

Pneumatic winches are relatively stable during operation and easy to operate. By controlling the flow and pressure of compressed air, the speed and traction of the winch can be easily adjusted, and even novices can quickly get started.

Pneumatic winches have become an indispensable and important equipment in the industrial field with their unique working principle, wide application fields, and significant advantages and characteristics, providing solid support for the development of many industries. With the continuous advancement of technology, pneumatic winches will continue to upgrade to bring more convenience and efficiency to industrial production.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى