Submit feedback

Pneumatic Chain Hoist: An efficient and safe lifting tool

2025.05.22

2025.05.22

Industry News

Industry News

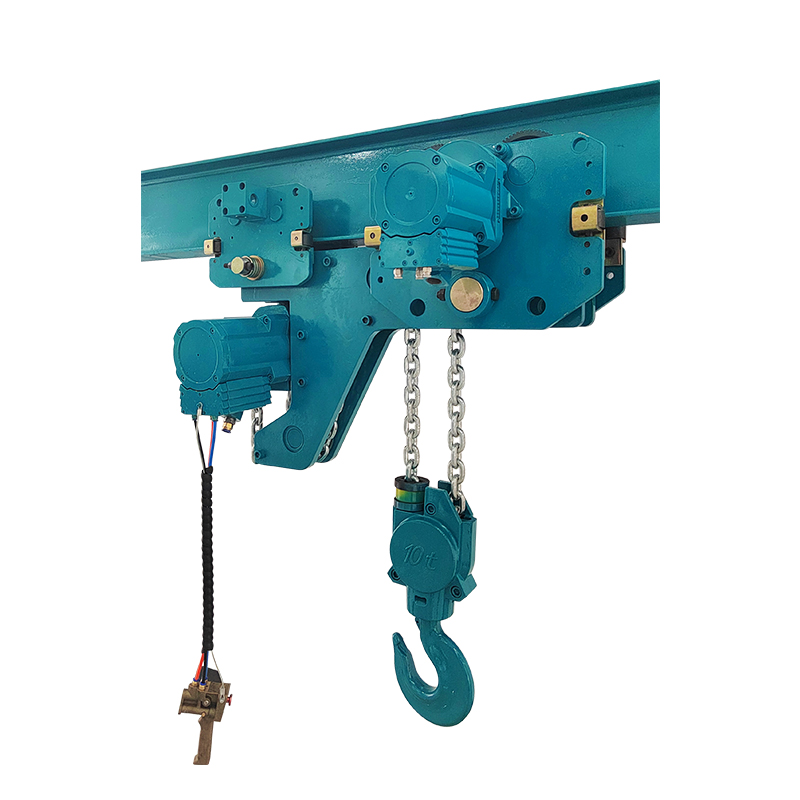

In modern industrial production, lifting equipment plays a vital role. Whether it is manufacturing, construction engineering, or logistics industry, lifting operations are almost the core of all heavy object handling. Although traditional electric cranes and electric hoists have performed well in many occasions, with the development of technology, Pneumatic Chain Hoist has gradually been widely used in some special environments. As an efficient, safe and environmentally friendly lifting equipment, Pneumatic Chain Hoist is becoming a new favorite in industrial lifting equipment with its unique advantages.

Working principle of Pneumatic Chain Hoist

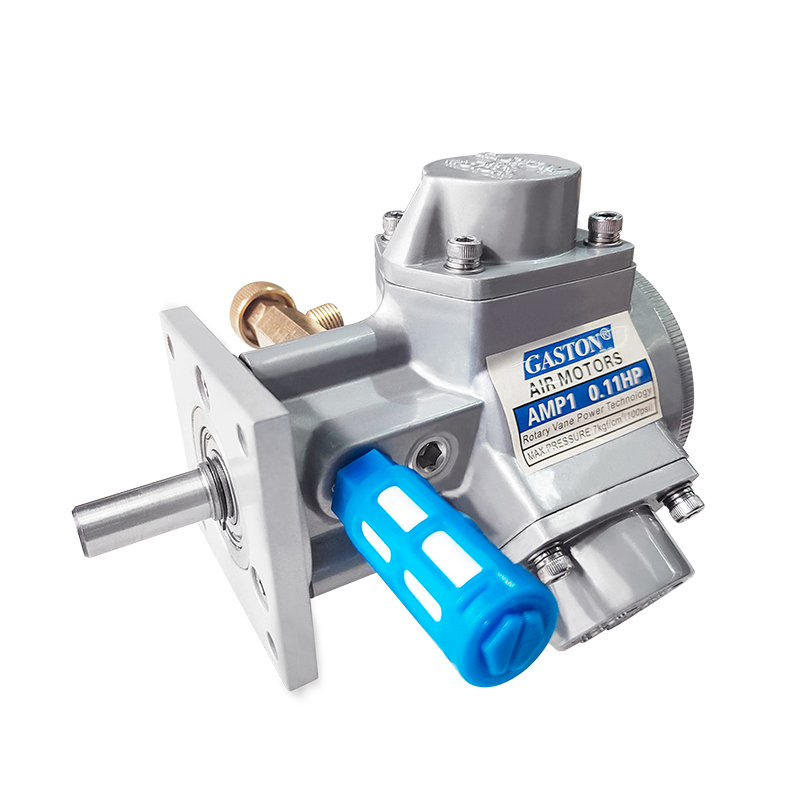

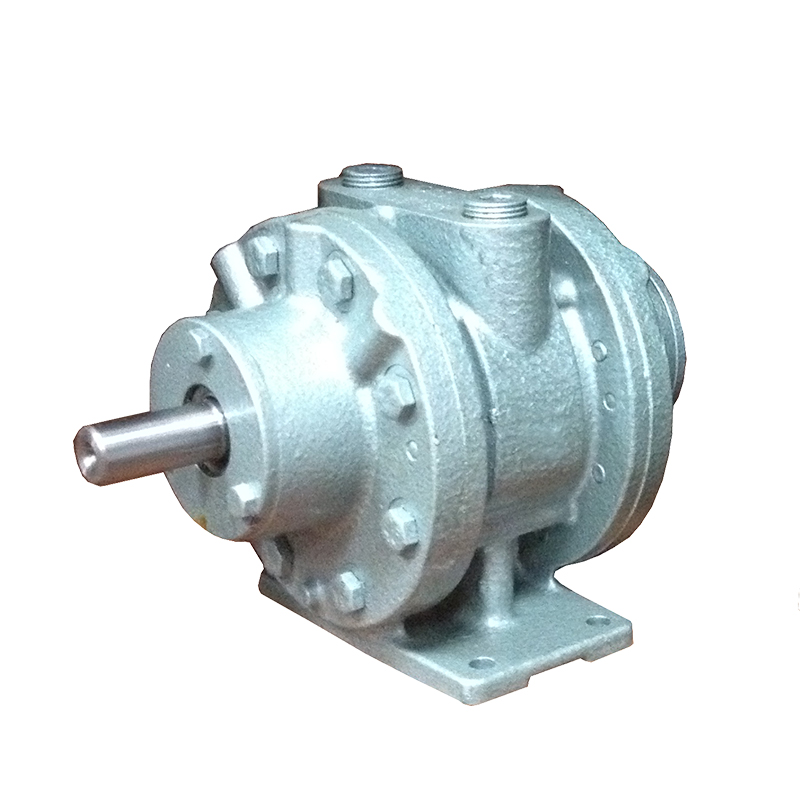

Pneumatic Chain Hoist is a lifting equipment that uses compressed air as a power source. Unlike traditional electric hoists, it does not rely on electricity, but drives the motor to rotate through air pressure, thereby driving the chain to lift or lower objects. The power source of the pneumatic system generally comes from an air compressor, which has the characteristics of simple structure and easy maintenance. Through the compression and release of air, pneumatic cranes can efficiently and stably complete lifting tasks, especially suitable for environments with insufficient power or high explosion-proof requirements.

Main advantages of Pneumatic Chain Hoist

1. Safety

One of the most significant advantages of pneumatic chain hoists is their extremely high safety. Since their power source is compressed air, there is no need to use electricity. This makes pneumatic hoists very suitable for use in explosive and flammable environments, avoiding sparks and electrical failures that may be caused when electrical equipment is used in hazardous areas. The design of pneumatic hoists usually includes functions such as anti-skid, overload protection and braking systems, which greatly improves the safety of operation.

2. Environmental protection and energy saving

Pneumatic chain hoists are more environmentally friendly than traditional electric hoists. It does not rely on electricity supply, but uses compressed air to drive, which reduces energy consumption. Pneumatic equipment generates almost no heat when working, which means that there will be no overheating problems caused by current overload like electric hoists, which prolongs the service life of the equipment.

3. Flexibility and adaptability

Pneumatic chain hoists are extremely adaptable. Whether in high or low temperatures, or in humid and dusty environments, they can maintain stable working performance. Especially in some factory workshops or outdoor construction sites with drastic temperature changes, pneumatic hoists can better adapt to different working conditions than electric hoists.

4. Low maintenance cost

The structure of pneumatic hoists is simple, and the use of air as a power source reduces the dependence on motors and electrical systems. Compared with electric hoists, pneumatic hoists are easier to maintain in daily maintenance, and the difficulty of repair and maintenance is relatively low. Although it still needs to regularly check the wear of the air compression system and the chain, in general, the maintenance cost of pneumatic chain hoists is low and they can maintain efficient operation for a long time.

Application field of Pneumatic Chain Hoist

Due to its unique advantages, Pneumatic Chain Hoist is widely used in many fields, especially in some environments where the power supply is unstable or explosion-proof is required.

In many dangerous environments such as chemical plants, oil fields, and natural gas refineries, electric equipment is prone to fire or explosion accidents due to electrical failures. Pneumatic hoists have become the preferred equipment for hoisting operations in these places because they do not involve electrical systems. Its safety greatly reduces the risk of accidents and provides more reliable protection for personnel in the workplace.

Pneumatic hoists can maintain stable operation in high or low temperature environments. This makes it irreplaceable in applications in metallurgy, mining and extremely cold regions. Even under harsh temperature conditions, pneumatic cranes can ensure efficient lifting work.

Pneumatic chain hoists also play a particularly prominent role in ship repair or port loading and unloading. Especially in the loading and unloading operations of offshore platforms or ships, due to the large wind and waves at sea, pneumatic hoists can provide stronger stability and reduce the risk of electric equipment being affected by the external environment.

From manufacturing to logistics, from construction sites to mines, Pneumatic Chain Hoist will help all walks of life improve work efficiency and ensure operational safety with its excellent performance and safety. With the continuous development of new materials and new technologies, Pneumatic Chain Hoist will show more abundant functions and broader application prospects in the future, becoming an ideal choice for industrial lifting operations.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى