Submit feedback

The Hidden Powerhouse: Discovering the World of Positive Displacement Pneumatic Motors

2025.07.22

2025.07.22

Industry News

Industry News

I. Introduction

A. Hook: The Power of Compressed Air

In the world of industrial automation and specialized machinery, the roar of a powerful engine or the hum of an electric motor often takes center stage. Yet, quietly and efficiently, another force has been at play for decades, offering unique advantages where conventional power sources fall short: the power of compressed air. This invisible, yet potent, medium drives a class of devices known as pneumatic motors, serving as the unsung heroes in countless applications.

B. What are Positive Displacement Pneumatic Motors?

A Positive Displacement Pneumatic Motor is a mechanical device that converts the energy of compressed air into mechanical rotary motion. Unlike turbine-style air motors that rely on the dynamic flow of air over blades, positive displacement motors operate on a volumetric principle. They trap a fixed volume of compressed air, allow it to expand, and then exhaust it, using the resulting pressure differential to create continuous rotary motion. This fundamental difference gives them distinct characteristics and advantages, particularly in demanding environments.

C. Brief History and Evolution

The concept of using compressed air for power dates back centuries, with early applications in mining and tunneling. The development of practical pneumatic motors gained traction in the 19th century, driven by the need for safer and more robust power sources in hazardous conditions where sparks from electric motors posed a significant risk. Over time, designs evolved from simple piston-driven mechanisms to more sophisticated vane and gear motors, each offering specific performance profiles suitable for a widening array of industrial and specialized applications.

D. Importance and Common Applications Overview

Positive displacement pneumatic motors are indispensable in industries where safety, durability, and precise control are paramount. They are commonly found powering hand tools in manufacturing, hoists in material handling, mixers in chemical plants, and specialized equipment in medical and food processing facilities. Their inherent safety in explosive atmospheres and their ability to stall without damage make them a preferred choice in many challenging operational settings.

E. Article Scope and What the Reader Will Learn

This article will delve into the fundamental principles governing positive displacement pneumatic motors, explore their various types, highlight their key advantages and limitations, and detail their diverse applications. We will also cover essential selection criteria and maintenance practices, concluding with a look at future trends in this vital technology.

II. Fundamentals of Pneumatic Motor Operation

A. Compressed Air as Energy Source

- Properties of Compressed Air Relevant to Motors: Compressed air acts as the working fluid, storing potential energy that is converted into kinetic energy. Its key properties for motor operation include its compressibility (allowing for energy storage), its ability to expand (driving the motor), and its relatively low viscosity (facilitating flow).

- Role of Air Pressure and Flow: The performance of a pneumatic motor is directly dependent on the supplied air pressure and flow rate. Pressure dictates the force available to drive the motor, while flow rate (volume of air per unit time) determines the motor's speed. Higher pressure generally leads to higher torque, and higher flow leads to higher speed.

B. Positive Displacement Principle Explained

- How a Fixed Volume of Air is Trapped and Expanded: The core of positive displacement lies in the motor's design, which creates sealed chambers. Compressed air enters these chambers, pushing a movable element (like a vane or piston). As the element moves, the volume of the chamber increases, allowing the air to expand and transfer its energy. Once the air has done its work, it is exhausted, and the cycle repeats. This "positive displacement" ensures that a specific volume of air is utilized in each cycle, providing predictable and controlled motion.

- Comparison to Other Motor Types (e.g., Turbines - Briefly): Unlike pneumatic turbines, which use the continuous flow of air to spin a rotor (similar to a windmill), positive displacement motors rely on discrete volumes of air acting on moving parts. This makes them generally more efficient at lower speeds and capable of higher starting torques compared to turbines of similar size.

C. Key Components (General)

While specific designs vary, most positive displacement pneumatic motors share common essential components:

- Rotor/Shaft: The central rotating component that converts the linear force from the expanding air into rotational motion, delivering power to the output.

- Housing: The outer casing that encloses all internal components, providing structural integrity and containing the compressed air.

- Inlet/Exhaust Ports: Openings through which compressed air enters the motor and spent air is expelled.

- Sealing Elements: Components like O-rings, gaskets, and precise machining that prevent air leakage between chambers and ensure efficient operation.

III. Types of Positive Displacement Pneumatic Motors

Positive displacement pneumatic motors come in several configurations, each suited for different applications based on their unique operating characteristics.

A. Vane Motors

- Description and Construction: Vane motors consist of a cylindrical rotor mounted eccentrically within a larger cylindrical housing. Rectangular vanes are fitted into radial slots in the rotor.

- How They Work: As compressed air enters the motor, it pushes against the vanes, forcing them outwards against the housing wall due to centrifugal force. The air then expands in the crescent-shaped chambers formed between the rotor, vanes, and housing, causing the rotor to turn. As the rotor turns, the vanes slide back into their slots, and the spent air is exhausted.

- Advantages: Vane motors are compact, offer good starting torque, are easily reversible by changing the air flow direction, and can operate at relatively high speeds.

- Disadvantages: They are susceptible to wear on the vanes and housing due to friction, and air leakage can occur if seals degrade, leading to reduced efficiency.

- Common Applications: Widely used in hand tools like grinders, drills, screwdrivers, and impact wrenches due to their compact size and high power-to-weight ratio.

B. Piston Motors

Piston motors are generally more robust and offer higher torque at lower speeds.

- Radial Piston Motors:

- Description and Construction: These motors feature multiple pistons (typically 3 to 6 or more) arranged radially around a central crankshaft.

- How They Work: Compressed air is directed sequentially to each piston, forcing it outwards. This linear motion is converted into rotary motion by the crankshaft, similar to an internal combustion engine.

- Advantages: Radial piston motors are known for their high torque output, excellent low-speed performance, and robust construction. They are very durable and can handle heavy loads.

- Disadvantages: They tend to be larger and heavier than vane motors for a given power output and are generally more complex in design.

- Common Applications: Ideal for applications requiring high torque and precise control at lower speeds, such as hoists, winches, mixers, and large industrial machinery.

- Axial Piston Motors (Less Common for Pneumatic):

- Brief Description: While more prevalent in hydraulic systems, axial piston designs for pneumatic motors exist but are less common. They typically involve pistons arranged parallel to the drive shaft, acting on a swash plate or wobble plate to generate rotary motion.

C. Gear Motors

- Description and Construction: Pneumatic gear motors typically consist of two meshing gears (external or internal) enclosed within a housing.

- How They Work: Compressed air enters the motor and is trapped in the pockets between the gear teeth and the housing. As the gears rotate, the air is carried around and then released through the exhaust port. The continuous flow of air into and out of these pockets creates the rotational force.

- Advantages: Gear motors are simple in design, very robust, and generally well-suited for high-speed applications. They are less prone to wear than vane motors in some conditions.

- Disadvantages: They typically offer lower starting torque compared to vane or piston motors and can be less efficient at very low speeds.

- Common Applications: Used in applications requiring consistent speed and moderate torque, such as conveyor drives, small pumps, and some mixing equipment.

D. Diaphragm Motors (Less Common as Rotary, More for Linear Actuation)

While primarily used for linear actuation (e.g., in valves or pumps), some rotary diaphragm motors exist. They use the deflection of a flexible diaphragm to drive a mechanism that translates linear motion into rotary motion. These are less common as primary rotary power sources but exemplify the positive displacement principle.

IV. Key Characteristics and Advantages

Positive displacement pneumatic motors offer several compelling advantages that make them the preferred choice in specific industrial contexts.

A. Safety in Hazardous Environments

- Non-Sparking Operation: Unlike electric motors, pneumatic motors do not use electricity and therefore do not generate sparks during operation. This is a critical safety feature in environments containing flammable gases, vapors, or dust.

- Explosion-Proof Nature: Their inherent design makes them intrinsically safe for use in explosive atmospheres (classified as ATEX zones or equivalent), significantly reducing the risk of ignition.

B. High Power-to-Weight Ratio

Pneumatic motors can deliver substantial power relative to their size and weight, making them ideal for portable tools and applications where space and weight are critical considerations.

C. Instantaneous Start, Stop, and Reversal

They can start, stop, and reverse direction almost instantaneously simply by controlling the air supply. This rapid response is crucial for applications requiring quick and precise movements.

D. Variable Speed and Torque Control

- Simple Throttling of Air Supply: The speed and torque of a pneumatic motor can be easily controlled by regulating the incoming air pressure and flow. This can be achieved with simple valves, offering flexible and intuitive operation.

E. Overload Protection (Stalling Without Damage)

A significant advantage is their ability to stall under overload conditions without sustaining damage. When the load exceeds the motor's torque capacity, it simply stops. Once the overload is removed, it can resume operation without requiring a reset or repair, unlike electric motors that can overheat and burn out.

F. Durability and Robustness

- Tolerance to Harsh Environments (Dust, Heat, Humidity): Pneumatic motors are inherently robust and can withstand harsh operating conditions, including high temperatures, dusty environments, and high humidity, which might compromise electric motors.

G. Cool Operation (Air Expansion Cools the Motor)

As compressed air expands within the motor, it causes a cooling effect. This means pneumatic motors generally run cooler than electric motors, reducing the risk of overheating and extending their lifespan, especially in continuous operation.

V. Disadvantages and Limitations

Despite their many advantages, positive displacement pneumatic motors also come with certain limitations that must be considered.

A. Energy Efficiency

- Lower Efficiency Compared to Electric Motors: Generally, pneumatic motors are less energy-efficient than their electric counterparts. The process of compressing air itself consumes a significant amount of energy, and there are inherent losses in the motor's operation.

- High Compressed Air Consumption: To deliver power, these motors require a continuous and substantial supply of compressed air, which can be costly to generate and maintain.

B. Noise Levels

Pneumatic motors can be quite noisy during operation, primarily due to the rapid exhaust of compressed air. Silencers and mufflers are often required to mitigate this issue, especially in indoor environments.

C. Air Quality Requirements

- Need for Filtered and Lubricated Air: For optimal performance and longevity, pneumatic motors require clean, dry, and often lubricated compressed air. Contaminants like moisture, dirt, and oil can cause wear, corrosion, and blockages.

- Impact of Contaminants: Poor air quality leads to increased maintenance, reduced efficiency, and premature failure of motor components.

D. Exhaust Air Management

- Potential for Noise and Oil Mist: The exhausted air can be loud and, if the air supply is lubricated, can release an oil mist into the environment, which may require ventilation or collection systems.

E. Cost of Compressed Air Infrastructure

Implementing a pneumatic system requires an investment in air compressors, dryers, filters, regulators, and distribution piping, which can be a significant upfront and ongoing cost.

VI. Applications of Positive Displacement Pneumatic Motors

The unique combination of safety, power, and control offered by positive displacement pneumatic motors makes them indispensable across a wide range of industries and applications.

A. Industrial Tools

They are the workhorses of many workshops and assembly lines, powering:

- Grinders: For material removal and finishing.

- Drills: For precise hole boring.

- Impact Wrenches: For high-torque fastening and loosening.

- Screwdrivers: For assembly tasks requiring controlled torque.

B. Material Handling

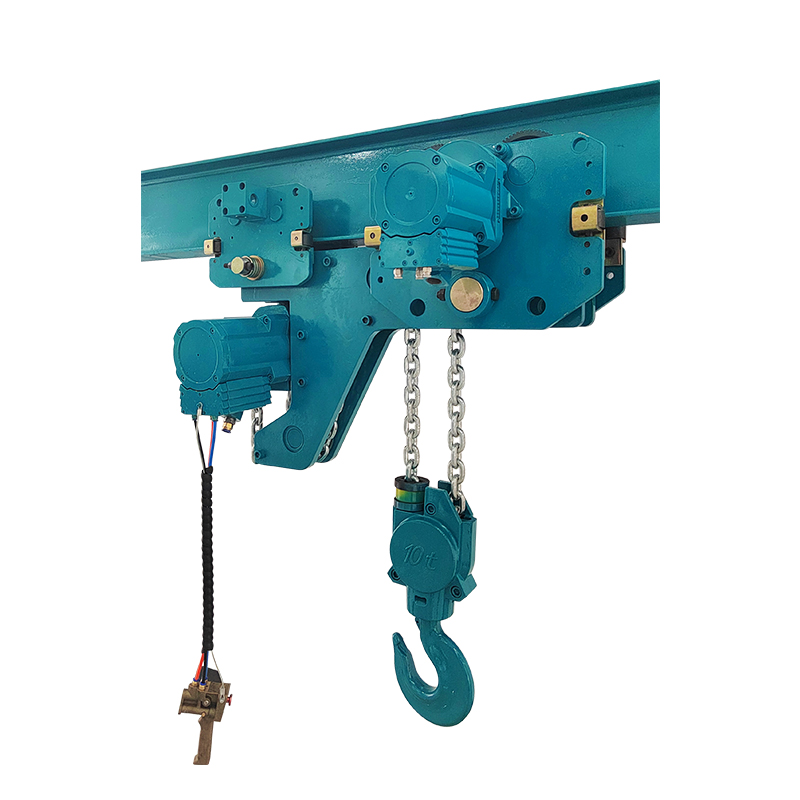

Their robust nature and ability to handle heavy loads make them ideal for:

- Hoists: For lifting and lowering heavy objects safely.

- Winches: For pulling and positioning loads.

- Conveyors: For driving material transport systems.

C. Mixing and Agitation

The non-sparking characteristic is crucial in environments with flammable materials:

- Paint Mixers: Ensuring uniform consistency without ignition risk.

- Chemical Agitators: Stirring corrosive or volatile substances safely.

D. Food and Beverage Industry

Their ability to withstand washdown and operate in sterile conditions is highly valued:

- Washdown Capabilities: Motors designed to resist water and cleaning agents.

- Sterile Environments: Used in processing and packaging where hygiene is paramount.

E. Mining and Construction

Their durability and resistance to harsh conditions are essential:

- Robustness in Harsh Conditions: Operating reliably in dusty, wet, and rugged environments.

F. Medical and Pharmaceutical

The non-magnetic properties and safety are critical for sensitive applications:

- Sterilization: Can be sterilized for use in medical devices.

- Non-Magnetic Properties: Safe for use near MRI machines and other sensitive electronic equipment.

G. Automotive Industry

From assembly lines to repair shops, they are used for various tasks requiring reliable power and control.

VII. Selection Criteria for Pneumatic Motors

Choosing the right pneumatic motor involves evaluating several key factors to ensure optimal performance and longevity for a given application.

| Criterion | Description |

|---|---|

| Power and Torque Requirements | Determine the necessary output power and torque for the application. This will dictate the motor's size and type (e.g., vane for higher speed, piston for higher torque). |

| Speed Range | Consider the required operating speed and whether variable speed control is necessary. |

| Air Consumption | Evaluate the motor's air consumption rate (CFM or L/min) to ensure it aligns with the available compressed air supply capacity. High consumption can lead to increased operating costs. |

| Operating Pressure | Match the motor's rated operating pressure to the available system pressure. |

| Size and Weight Constraints | Account for the physical dimensions and weight of the motor, especially for portable tools or space-constrained installations. |

| Environmental Conditions | Assess the operating environment for factors like temperature, humidity, dust, and the presence of hazardous materials, choosing a motor designed to withstand these conditions. |

| Reversibility Needs | Determine if the application requires the motor to operate in both clockwise and counter-clockwise directions. Most vane and piston motors are easily reversible. |

| Maintenance and Serviceability | Consider the ease of maintenance, availability of spare parts, and the expected lifespan of the motor. |

VIII. Maintenance and Troubleshooting

Proper maintenance is crucial for ensuring the long-term reliability and efficiency of positive displacement pneumatic motors.

A. Regular Lubrication

Most pneumatic motors require lubrication, often through an in-line lubricator that adds a fine mist of oil to the compressed air. Regular checks and refills of the lubricator are essential.

B. Air Filtration and Regulation

Ensure that the compressed air supply is properly filtered to remove contaminants (dirt, rust, moisture) and regulated to the correct operating pressure. Filters should be cleaned or replaced regularly.

C. Inspection for Wear and Tear

Periodically inspect the motor for signs of wear on components like vanes, pistons, bearings, and seals. Address any issues promptly to prevent further damage.

D. Common Issues and Solutions

- Loss of Power: Could be due to insufficient air pressure/flow, worn internal components (e.g., vanes, seals), or clogged air filters.

- Excessive Air Consumption: Often indicates internal air leakage due to worn seals or damaged components.

- Overheating: While rare, can occur if the motor is continuously overloaded or if lubrication is insufficient.

- Noise: May indicate worn bearings, misaligned components, or simply the need for a more effective muffler.

IX. Future Trends and Conclusion

A. Advancements in Efficiency and Materials

Ongoing research focuses on improving the energy efficiency of pneumatic motors through advanced designs, better sealing technologies, and the use of new, low-friction materials. This aims to reduce compressed air consumption and make them more competitive with electric motors in a wider range of applications.

B. Integration with Control Systems

Modern pneumatic motors are increasingly being integrated with sophisticated control systems, including proportional valves and sensors, allowing for more precise speed, torque, and position control. This enhances their versatility in automated processes.

C. Continued Relevance in Niche Applications

Despite the rise of electric drives, positive displacement pneumatic motors will continue to hold a vital place in niche applications where their inherent safety, robustness, and ability to operate in harsh or hazardous environments remain unparalleled.

D. Summary of Key Benefits and Their Enduring Value

In summary, positive displacement pneumatic motors offer a unique blend of safety, power density, instant control, and durability. Their ability to operate without sparks, withstand harsh conditions, and stall without damage makes them indispensable tools in industries ranging from manufacturing and construction to medical and food processing.

E. Final Thoughts on the Role of Pneumatic Motors in Modern Industry

While perhaps not as universally visible as electric motors, positive displacement pneumatic motors are a testament to the ingenuity of engineering. They continue to be a reliable, powerful, and safe solution for critical tasks, proving that the simple yet effective power of compressed air remains a cornerstone of modern industrial capability. As technology advances, these motors will likely continue to evolve, becoming even more efficient and integrated, ensuring their enduring role in a diverse and demanding industrial landscape.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى