Submit feedback

Pneumatic Air Winch: A tool that combines high efficiency and safety

2025.05.01

2025.05.01

Industry News

Industry News

In the industrial field, especially in heavy machinery and lifting operations, Pneumatic Air Winch has gradually become an important tool in modern engineering with its unique working principle and significant advantages. Pneumatic air winches can not only effectively improve work efficiency, but also become the preferred equipment of more and more companies due to its easy operation, low maintenance cost and strong durability.

Pneumatic air winches are equipment that rely on compressed air as a power source to operate. Unlike traditional electric or hydraulic winches, pneumatic winches use air compressors to deliver high-pressure air to the pneumatic motor inside the winch to drive the drum of the winch to rotate, thereby realizing the lifting, traction or pulling functions of objects. Due to the use of air power, one of the biggest advantages of pneumatic air winches is that they do not need to rely on power supply, so they can operate safely and stably in some places where electricity is difficult to access, or in environments where there are sparks and explosion hazards.

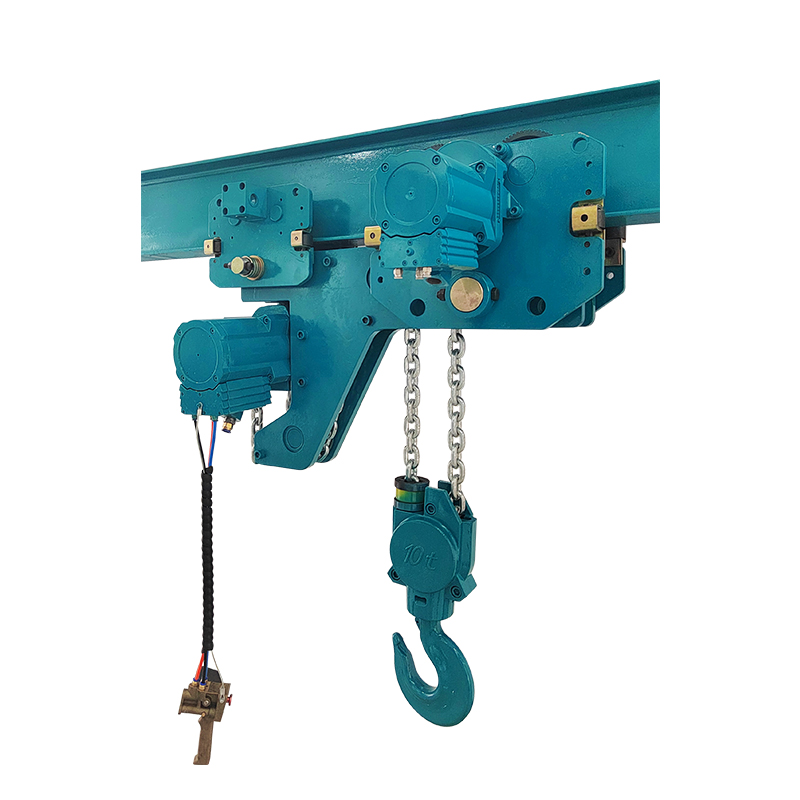

The core components of pneumatic winches include pneumatic motors, reducers, brake systems, winch drums and control valves. By adjusting the air pressure, the operator can control the speed and pulling force of the winch, thereby achieving precise lifting and traction operations. Pneumatic air winches are generally equipped with efficient automatic braking devices to ensure that the winch can stop in time when the load is too heavy or the air is suddenly cut off to avoid equipment damage or personal injury.

Pneumatic air winches are widely used in various work occasions that require lifting, pulling, traction or lifting. In the fields of shipbuilding, offshore oil platforms, mining, construction engineering, etc., pneumatic winches provide unparalleled advantages. Especially in marine operations and underground operations, pneumatic winches have become the preferred tool for many high-risk and high-intensity operations because of their characteristics of not being restricted by electricity.

In construction and mining operations, the traction and convenience of pneumatic winches make them an ideal choice for lifting heavy objects. Especially in some remote areas where there is a lack of power facilities, the application of pneumatic winches is more advantageous. It can complete tasks with low maintenance costs and extremely high reliability, and is not easily interrupted by power failures.

Compared with traditional electric winches, pneumatic air winches have a series of unique advantages, which make them occupy an important position in many industrial operations. Pneumatic winches do not require electricity, which makes them able to operate efficiently in environments where electricity is insufficient or inaccessible, and have great flexibility and adaptability. Pneumatic winches are usually easier to operate, and operators only need to adjust the air pressure to achieve precise control of speed and force.

Pneumatic winches are safer. Traditional electric winches are prone to safety hazards such as short circuits or fires due to electrical equipment failures, while pneumatic winches transmit power through compressed air, completely avoiding this risk. Therefore, pneumatic air winches are particularly important in some working environments that are highly sensitive to sparks or electrical failures.

Another major advantage of pneumatic air winches is their efficient power transmission. Pneumatic motors can provide smooth and long-lasting power output, which can not only withstand higher loads, but also have extremely fast response speeds, making them suitable for environments with frequent operations. Moreover, since the power source of pneumatic winches is compressed air, they can operate continuously and are less likely to overheat or damage equipment due to long-term work.

The maintenance cost of pneumatic air winches is relatively low. Compared with the hydraulic system, which requires regular oil replacement and pipeline maintenance, the maintenance requirements of pneumatic winches are relatively simple. It only requires regular inspection of the pneumatic system and replacement of some vulnerable parts. The service life of pneumatic motors is usually longer, which greatly reduces the overall operating costs of the enterprise.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى