Submit feedback

Pneumatic Air Driven Mixers: A Game-Changer in Industrial Mixing Solutions

2025.05.08

2025.05.08

Industry News

Industry News

In modern industrial applications, achieving the perfect blend of materials is crucial for the efficiency and quality of manufacturing processes. Whether in the food, chemical, pharmaceutical, or paint industries, mixing plays a pivotal role in ensuring consistent product quality. Among the diverse range of mixing technologies available today, pneumatic air-driven mixers have emerged as an efficient and reliable solution for a variety of mixing needs.

Pneumatic air-driven mixers operate using compressed air, rather than relying on electricity or hydraulic power to drive the mixing mechanism. This characteristic offers several distinct advantages, especially in environments where traditional electric motors may not be suitable due to safety concerns, such as in hazardous or explosive atmospheres. The pneumatic system provides the necessary torque and speed for mixing, controlled by adjusting the air pressure, which directly influences the performance and efficiency of the mixer.

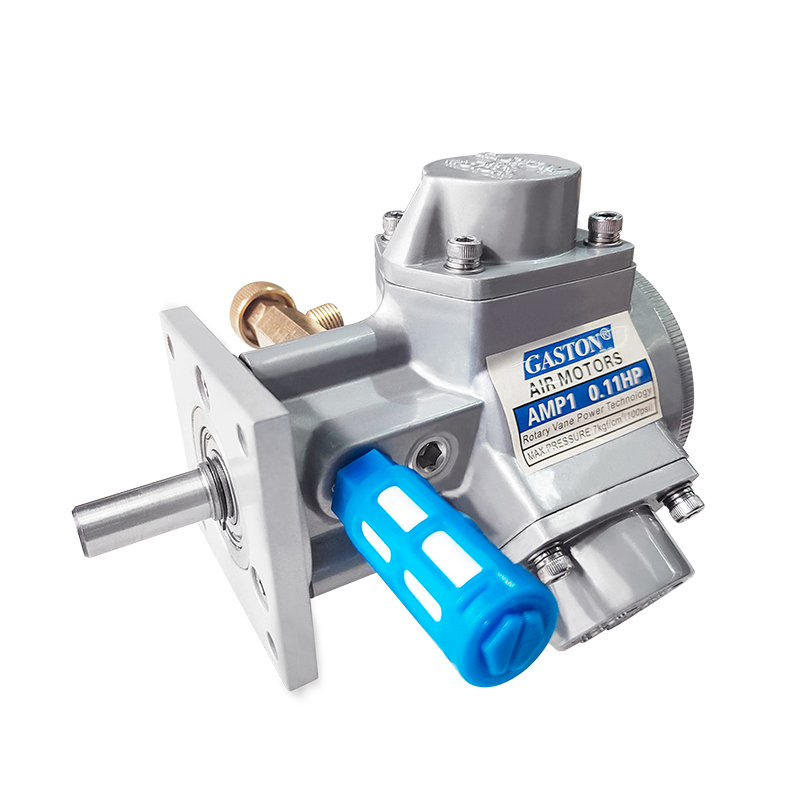

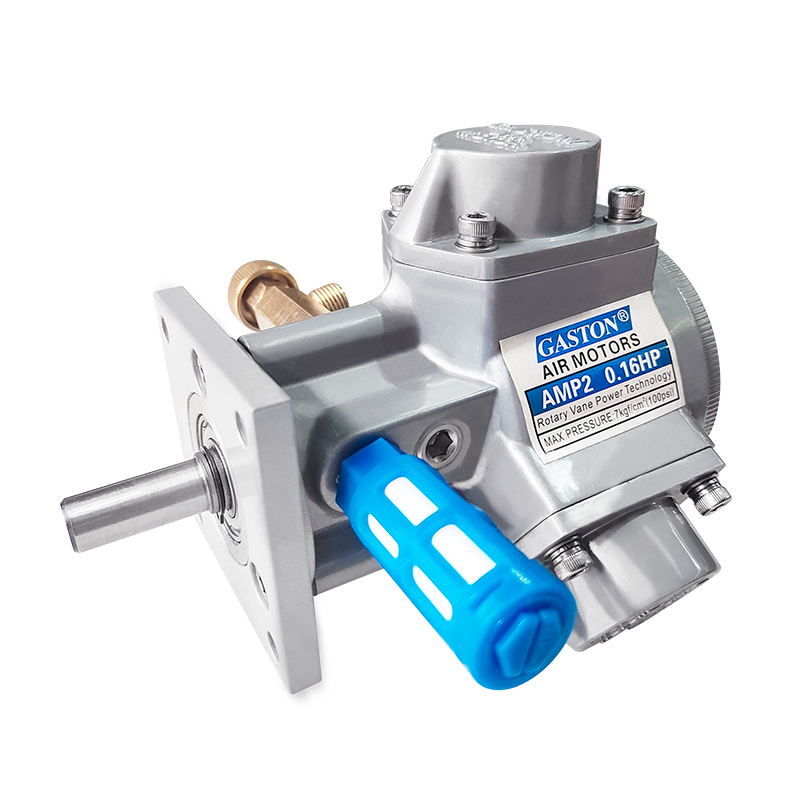

One of the primary components of a pneumatic air-driven mixer is the air motor, which powers the mixing impeller or agitator. These motors are designed to operate smoothly and consistently, offering high torque at relatively low speeds, which is ideal for applications requiring gentle or thorough mixing. The air motor’s speed can be adjusted by regulating the airflow, allowing for precise control over the mixing process. This flexibility is particularly beneficial when dealing with different viscosities or materials that require varying levels of agitation.

One of the standout benefits of pneumatic air-driven mixers is their safety profile. In industries where flammable or volatile substances are involved, the risk of sparks or overheating from electrical motors is a significant concern. Pneumatic mixers, however, eliminate this risk entirely because they are inherently explosion-proof. This makes them an excellent choice for industries such as pharmaceuticals, chemicals, and food production, where safety standards are stringent and non-negotiable.

Another key advantage is the versatility and ease of use these mixers offer. Unlike electric or hydraulic systems, which can be complicated and require maintenance of intricate components, pneumatic air-driven mixers are relatively simple and easy to maintain. The air motor components are fewer, and with fewer moving parts, there is a reduced risk of mechanical failure. This also means that pneumatic mixers are typically more durable and can withstand harsh operating conditions, including high temperatures, humidity, and exposure to corrosive substances.

Pneumatic mixers are highly adaptable. The speed control offered by varying air pressure allows operators to fine-tune the mixer to suit different materials and processes. Whether mixing low-viscosity liquids or highly viscous pastes, pneumatic air-driven mixers can be adjusted to ensure optimal mixing efficiency. This makes them suitable for a wide range of applications, from the delicate mixing of pharmaceutical ingredients to the robust blending of industrial coatings or adhesives.

In addition to their safety and durability, pneumatic air-driven mixers are also cost-effective, especially in long-term operations. Since they rely on compressed air, which is often available in many industrial settings, the operational costs can be lower compared to electric or hydraulic systems. Air-driven mixers require minimal maintenance, reducing downtime and repair costs.

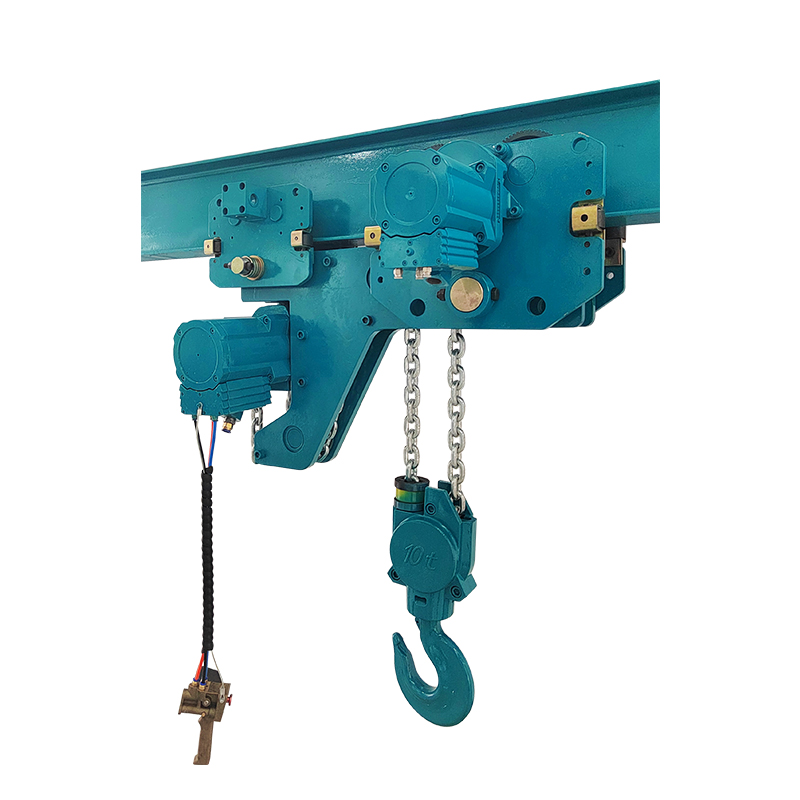

The ability to operate in a wide range of environments without the need for electrical connections also makes pneumatic mixers ideal for portable mixing applications. This is particularly useful in situations where the mixer needs to be moved between different areas or production lines, providing flexibility in how resources are utilized across a facility.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى