Submit feedback

About Us

The company has been committed to product innovation for many years, focusing on the updating and upgrading of pneumatic motors. With fine concepts and continuous investment, it has created a creative design team and has designed multiple innovative pneumatic products. Currently, it has independent intellectual property rights and has obtained more than 30 product patents.

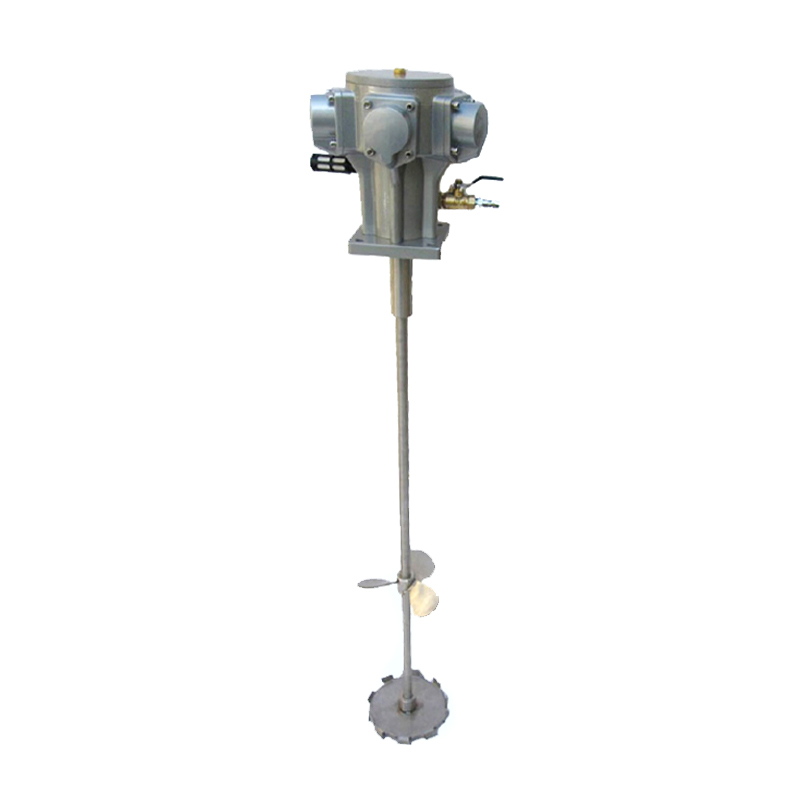

The company's main products include pneumatic motors and a series of products such as pneumatic hoists, pneumatic winches, pneumatic mixers, pneumatic emulsifiers, pneumatic explosion-proof pumps, pneumatic mixers, pneumatic fans, and industrial automation equipment pneumatic control system engineering developed based on specific production needs.

The company strictly follows the ISO9001 quality management system for product design, production, assembly, and testing. With the efforts of all employees, the company has passed the ISO9001 international quality system certification. Through strict procedures and high standards of auditing, the company has successfully passed the recognition of a "national high-tech enterprise". Gaston Company is gradually moving towards internationalization with its own strength and a global perspective.

Users with different needs will always be the coordinates we strive for and the driving force for constantly surpassing ourselves and striving for innovation! Gaston Company looks forward to sincere cooperation with friends from all walks of life at home and abroad to create brilliance together!

Honor Certificate

Latest News

-

Industry News 2025-09-22

With the advancement of industrial automation technology, pneumatic pumps, as an efficient and relia...

View More -

Industry News 2025-09-15

In modern industry, pneumatic industrial fans have become indispensable equipment in many sectors du...

View More -

Industry News 2025-09-08

In modern industrial production systems, the performance of power units directly determines the effi...

View More -

Industry News 2025-09-01

In modern industry, the choice of power transmission equipment directly impacts production efficienc...

View More -

Industry News 2025-08-22

In the vast arena of modern industrial production, lifting equipment is an indispensable "behind-the...

View More

Contact Us Now

Vertical Pneumatic Mixer Industry knowledge

In the chemical mixing industry, what are the biggest advantages of Vertical Pneumatic Mixer compared to traditional electric mixers?

In the chemical mixing industry, the biggest advantages of Vertical Pneumatic Mixer (vertical pneumatic mixer) compared to traditional electric mixers are mainly reflected in the following aspects:

1. Safety

No electric sparks and arcs: Pneumatic mixers are driven by air pressure, so no electric sparks or arcs are generated during operation, which is extremely safe when handling flammable and explosive chemical raw materials. This feature makes Vertical Pneumatic Mixer a safer choice in specific occasions in the chemical industry, such as mixing processes involving hazardous chemicals.

Explosion-proof design: Since they do not rely on electric drive, pneumatic mixers usually have better explosion-proof performance and are suitable for chemical production environments that require high safety.

2. Adaptability

Applicable to various liquids: Pneumatic mixers can be used for liquids of various properties, including high-viscosity and highly corrosive liquids. This is because the air pressure drive method is insensitive to the properties of the liquid and can work stably.

Strong environmental adaptability: In a humid, dusty or corrosive chemical production environment, electric mixers may be affected by damage to electrical components, while pneumatic mixers can better adapt to these harsh environments.

3. Maintenance and operation

Low maintenance cost: The structure of pneumatic mixers is relatively simple, and since they do not involve complex electrical components, their maintenance costs are usually low. At the same time, since there is no need to frequently replace vulnerable electrical components, the maintenance cost of long-term use is also reduced.

Easy operation: The operation of pneumatic mixers is relatively simple. You only need to control the air pressure source to achieve the mixing operation, without the need for a complex electrical control system.

4. Stable performance

Stable operation: The pneumatic mixer has a high working stability and is not affected by external factors such as power fluctuations, which can ensure the continuity and stability of the mixing process.

High mixing efficiency: By optimizing air pressure control and agitator design, pneumatic mixers can achieve efficient mixing effects and meet the requirements of chemical production for mixing uniformity.

In the food processing industry, there are extremely high requirements for hygiene standards. How does the Vertical Pneumatic Mixer meet the requirements of food-grade stainless steel materials and ensure a sterile operating environment during the production process?

In the food processing industry, the Vertical Pneumatic Mixer (vertical pneumatic mixer) usually takes the following measures to meet the requirements of food-grade stainless steel materials and ensure a sterile operating environment during the production process:

1. Meet the requirements of food-grade stainless steel materials

Material selection:

Food-grade stainless steel: The food-contact parts of the Vertical Pneumatic Mixer, including the agitator, mixing barrel, pipes, etc., are all made of stainless steel that meets food-grade standards, such as 304 or 316 stainless steel. These materials have corrosion resistance and good hygiene properties, which can ensure that food will not be contaminated during the mixing process.

Non-toxic and harmless materials: In addition to stainless steel, other parts that do not contact food but may indirectly affect food safety, such as seals, fasteners, etc., also need to use non-toxic and harmless materials to avoid contamination of food.

Material certification:

The manufacturer will ensure that the materials used are certified by relevant authoritative organizations, such as FDA, EU CE, etc., to prove that they meet food-grade standards.

2. Ensure a sterile operating environment

Sterile design:

Sealing: The design of the Vertical Pneumatic Mixer must have good sealing to prevent external air and microorganisms from entering the mixing system. The mixing barrel, pipe joints, etc. all use reliable sealing structures to ensure that there is no leakage during the mixing process.

Easy to clean structure: The design of the mixer should be easy to disassemble and clean to reduce cleaning dead corners and residues. The inner wall of the mixing barrel should be smooth and free of bumps, which is easy to clean and disinfect.

Cleaning and disinfection:

Cleaning procedures: Develop strict cleaning procedures, including comprehensive cleaning before, after and regularly. Cleaning agents that meet food safety standards should be used during the cleaning process, and ensure that there is no residue.

Disinfection measures: After cleaning, the mixer and its accessories must be disinfected. Disinfection methods can be selected according to specific circumstances, such as hot water disinfection, chemical disinfectant disinfection, etc.

Sterile operation specifications:

Personnel hygiene: Operators must wear clean clothes, gloves, shoe covers, etc. that meet the requirements, and accept strict personnel hygiene management. Before entering the mixing area, wash hands, dry, air shower and other procedures are required to ensure that the body surface is sterile.

Environmental control: The mixing area should be kept clean, dry, and well ventilated, and air cleanliness and microbial testing should be performed regularly. If necessary, an air purification system can be installed to further reduce the microbial content in the air.

Monitoring and recording:

Environmental monitoring: Regularly test the air cleanliness, microbial limit, temperature and humidity in the mixing area, and record the monitoring results. If any abnormal situation occurs, appropriate measures should be taken in time to ensure food safety.

Equipment maintenance: Regularly maintain and service the Vertical Pneumatic Mixer, including checking the sealing, cleaning effect, disinfection effect, etc., to ensure that it is always in good working condition.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى