Submit feedback

Pneumatic Chain Hoists: The Ultimate Choice for Industrial Lifting

2025.08.22

2025.08.22

Industry News

Industry News

In the vast arena of modern industrial production, lifting equipment is an indispensable "behind-the-scenes hero," silently supporting the smooth operation of various production processes. Among them, pneumatic chain hoists, with their unique appeal and superior performance, have gradually emerged as trusted partners in numerous industries.

Explore the Working Principle and Experience the Technology's Essence

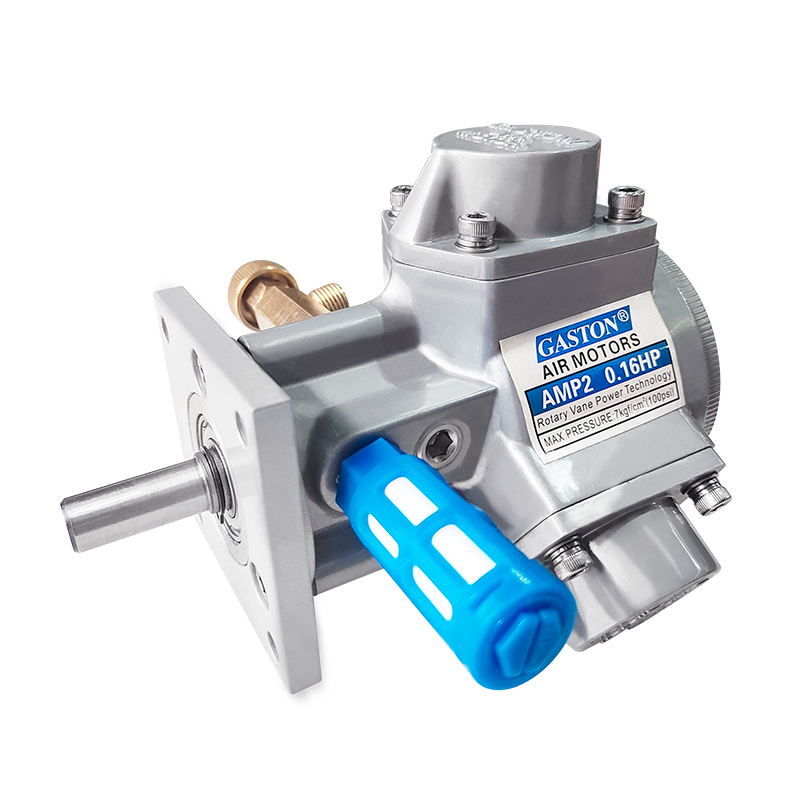

The pneumatic chain hoist's operating principle is based on an ingenious pneumatic mechanism. Its core components include the lifting mechanism, travel mechanism, and air distribution system. The lifting mechanism, the "heart" of the entire equipment, primarily consists of an air motor, planetary reducer, suspension assembly, brake, lifting chain, hook assembly, and main control valve. When compressed air is input as a power source, the air motor responds first, converting the compressed air's energy into mechanical energy, driving the planetary reducer. The planetary reducer then plays a key role in precisely controlling speed and torque, ensuring smooth and accurate power output. Precise control of the main control valve allows for easy raising and lowering of the hoisted load. The on-off brake provides positioning braking during the lifting and lowering process, ensuring safe lifting operations. The hoist mechanism can be installed securely or flexibly positioned beneath the travel mechanism for mobile operation, adapting to diverse work scenarios.

The travel mechanism is equally impressive, featuring a pneumatic trolley design comprised of active and passive wheels, along with a wall panel. The main control valve precisely controls the pneumatic motor and planetary reducer, driving the active wheels for steady movement and achieving horizontal displacement of the hoisted load, significantly expanding the operating range of the pneumatic chain hoist.

The air distribution system, like the equipment's "neural network," uses compressed air as its power source to systematically control the air circuits, manipulating the hoist's lifting and traveling movements. This seamless coordination of all components allows for complex and efficient lifting tasks.

Analyzing Unique Advantages and Demonstrating Extraordinary Value

Safety and Reliability, Safeguarding Production

Safety is always a top priority in industrial production, and the pneumatic chain hoist excels in this regard. Its internal gears undergo a high-temperature quenching treatment, creating a sturdy "armor" that significantly enhances wear resistance and toughness, ensuring the equipment maintains high stability and reliability even during long-term, high-intensity operation. The meticulously designed braking mechanism acts as a loyal "guardian," quickly and forcefully locking the chain and hook at any time and in any location, resolutely preventing the accidental fall of heavy objects and creating an impenetrable safety barrier for the production site. Furthermore, the pneumatic chain hoist is equipped with a gas shut-off protection function. In the event of a sudden gas shut-off, the protection mechanism automatically activates, ensuring that the workpiece remains firmly in place and preventing accidents caused by gas shut-off. This further enhances safety during operation and provides peace of mind for operators. Adapting to Complex Environments and Facing Tough Challenges

Industrial production environments vary widely, and many are fraught with challenges, such as humid workshops, dusty warehouses, and flammable and explosive chemical sites. However, the pneumatic chain hoist, with its exceptional adaptability, stands out in these complex environments. Its specially designed internal lubrication system effectively eliminates air pollution, extending the equipment's lifespan and ensuring stable operation in harsh environments. It remains unaffected by moisture erosion in humid environments, and resists dust interference, ensuring continuous and efficient operation in high-dust environments. Its spark-free nature makes it an ideal choice for hazardous areas like those prone to flammable and explosive environments, providing a reliable lifting solution for industrial production in these challenging environments.

High Efficiency and Energy Saving, Leading the Way in Green Production

In the era of striving for efficient production and energy conservation and environmental protection, the pneumatic chain hoist has demonstrated strong competitiveness. It operates by relying solely on compressed air at a certain pressure, achieving a perfect combination of low energy consumption and high efficiency. Compared to traditional electric hoists, pneumatic chain hoists offer exceptional operating speeds, often reaching several times the speed of electric hoists. This significantly reduces lifting time and significantly improves work efficiency. When lifting or lowering loads, they feature stepless speed regulation, allowing operators to precisely control speed based on actual needs and achieve rapid response. Whether performing delicate positioning operations or large-scale material handling, they can easily handle these tasks, providing a powerful impetus for efficient production.

Experienced in Wide Applications, Witnessed by Strength

Pneumatic chain hoists, with their superior performance and unique advantages, have found widespread application in numerous industries, becoming a vital force driving their development.

In the petroleum and chemical industries, the presence of large quantities of flammable and explosive substances during production places extremely high demands on the safety of lifting equipment. Pneumatic chain hoists, with their excellent explosion-proof performance, are the preferred equipment in this industry. Whether installing large storage tanks in refineries, handling chemical raw materials, or maintaining equipment in hazardous areas, pneumatic chain hoists operate stably and safely, providing a strong guarantee for safe production in the petroleum and chemical industries. The coal mining industry also relies on pneumatic chain hoists. In the complex underground environment, humidity, high dust levels, and the potential for gas explosions pose a constant threat to production safety. With their ability to adapt to harsh environments and reliable explosion-proof performance, pneumatic chain hoists play a key role in material lifting, equipment installation, and maintenance in coal mines, contributing to safe production.

In the logistics and port industries, rapid loading and unloading and efficient handling of cargo are key to improving operational efficiency. The high speed and flexible operation of pneumatic chain hoists make them an ideal choice for logistics and port operations. They can quickly unload cargo from transport vehicles and transport it to designated locations, significantly reducing cargo turnover time and improving logistics efficiency, adding a strong impetus to the booming logistics and port industries.

As a shining star in the industrial lifting field, the pneumatic chain hoist, with its unique operating principle, outstanding advantages, and wide range of applications, provides a solid foundation for the efficient and safe operation of modern industrial production. We believe that it will continue to shine brightly in the future, constantly innovating and developing, and writing a brilliant chapter in the progress of the industrial sector.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى