Submit feedback

Pneumatic Air Driven Mixers: A High-Efficiency Power Solution for Industrial Mixing

2025.08.15

2025.08.15

Industry News

Industry News

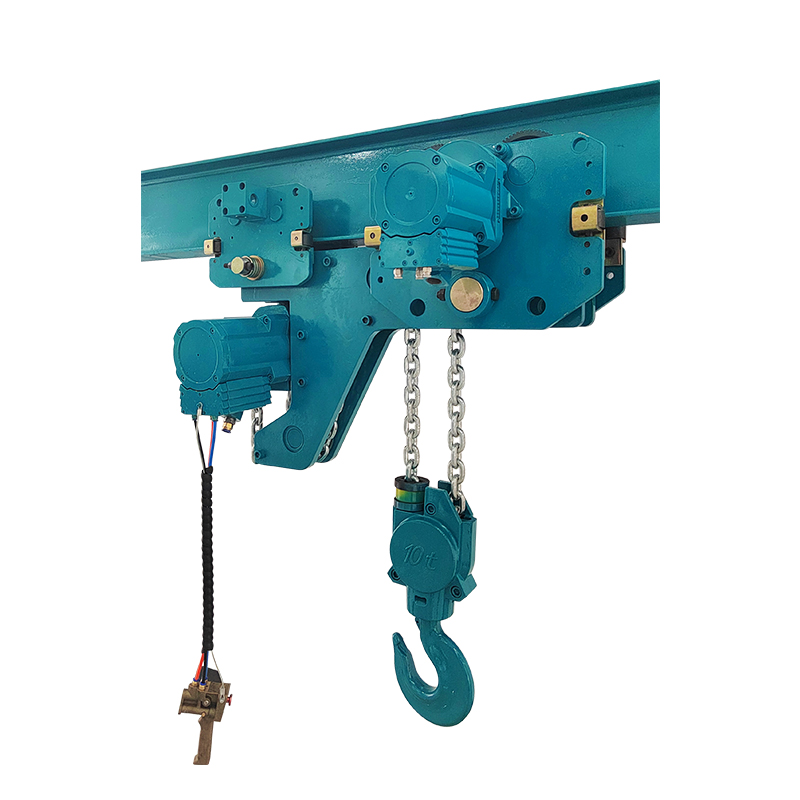

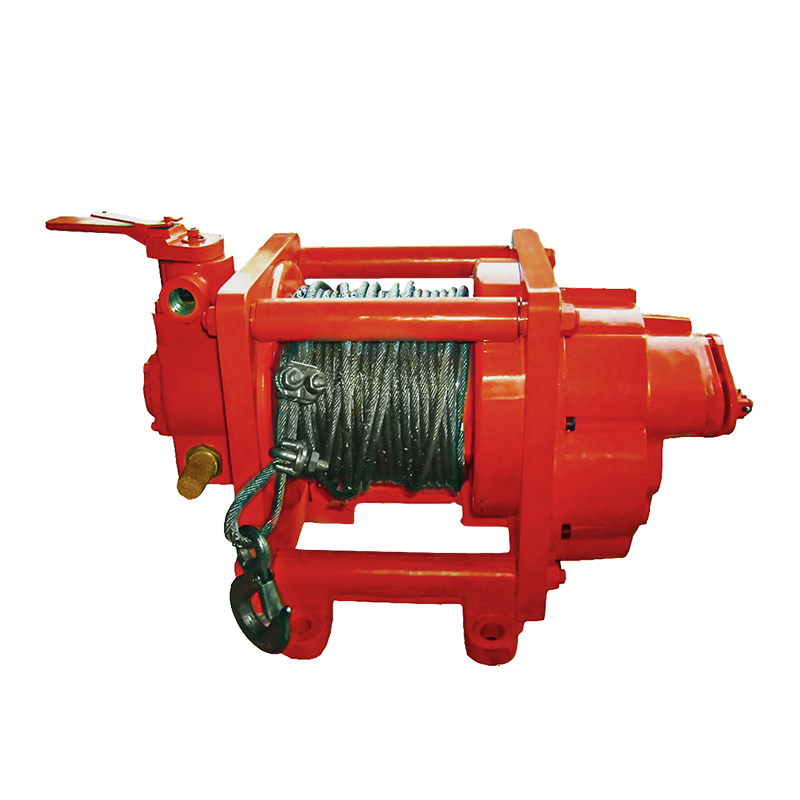

In modern industrial production, mixing equipment is a core component of material handling, and its performance directly impacts product quality and production efficiency. Pneumatic Air Driven Mixers, with their unique power transmission method and adaptability, have gained a significant position in diverse industries, including chemical, pharmaceutical, and food. Compared to traditional electric mixing equipment, this compressed air-powered mixing system, with its safety, reliability, and flexible control, has become a preferred solution in demanding production environments.

The Core Advantage of Pneumatic Drive: Dual Guarantee of Safety and Adaptability

The core competitiveness of pneumatic mixers stems from their unique power transmission mechanism. Compressed air drives the pneumatic motor, which in turn drives the impeller to mix materials. Since no electricity is directly used for power output, the risk of sparks is fundamentally eliminated, making them an irreplaceable safety feature in flammable and explosive environments. This spark-free design is a key factor in ensuring production safety when handling hazardous materials such as organic solvents and volatile chemicals. At the same time, the characteristics of the pneumatic system give the equipment exceptional environmental adaptability. Whether operating in high-temperature, high-humidity conditions or in harsh environments with dust and corrosive gases, pneumatic agitators maintain stable operation. Their structural design reduces the use of precision electronic components, minimizing the impact of environmental factors on equipment performance. This allows pneumatic agitators to function continuously in situations where traditional electric equipment struggles, providing strong support for production continuity.

Flexible Control and Efficient Mixing: Precise Process Adaptation

In industrial production, the mixing requirements of different materials often vary significantly. From simple stirring of low-viscosity liquids to uniform dispersion of high-viscosity slurries, the requirements for stirring speed and force vary widely. Pneumatic agitators achieve infinitely variable stirring speeds by adjusting the pressure and flow of compressed air. This flexible control capability allows precise matching to diverse process requirements. Operators can adjust the stirring intensity in real time based on the material's state, avoiding changes in material properties caused by over-agitation while ensuring that the mixing effect meets process standards.

Efficient energy conversion is also a prominent feature of pneumatic agitators. Compressed air drives the motor with minimal energy loss, and the power output is directly applied to the impeller, reducing energy waste in intermediate stages. In production scenarios with long, continuous operations, this efficient energy utilization not only reduces operating costs but also reduces equipment heat generation and extends service life. Furthermore, the equipment generates low noise during operation, improving the working environment in the production workshop and meeting the requirements of modern industry for green production.

Structural Design and Maintenance Features: Key to Improving Production Stability

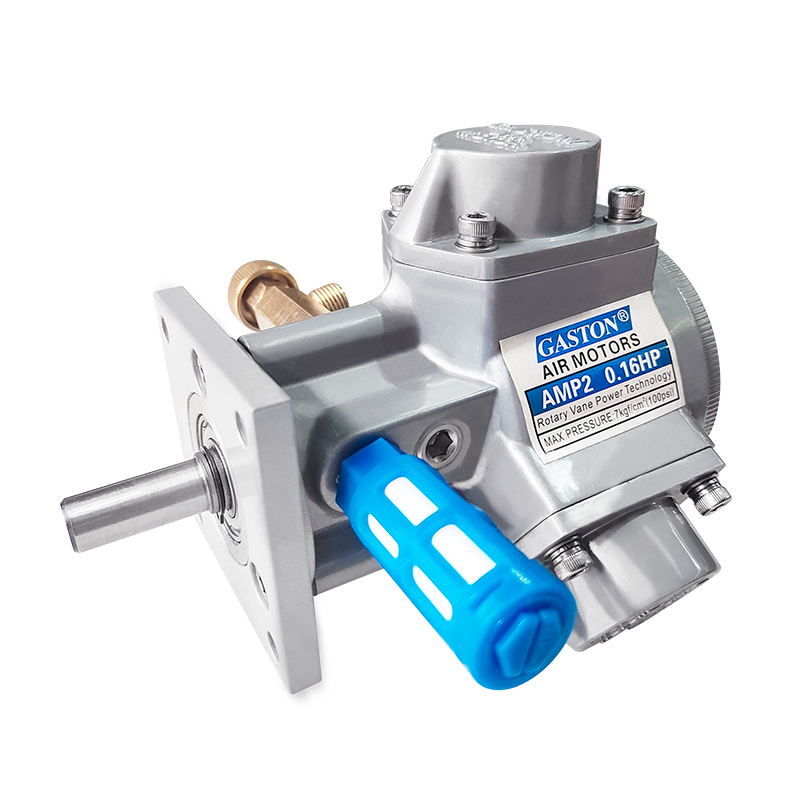

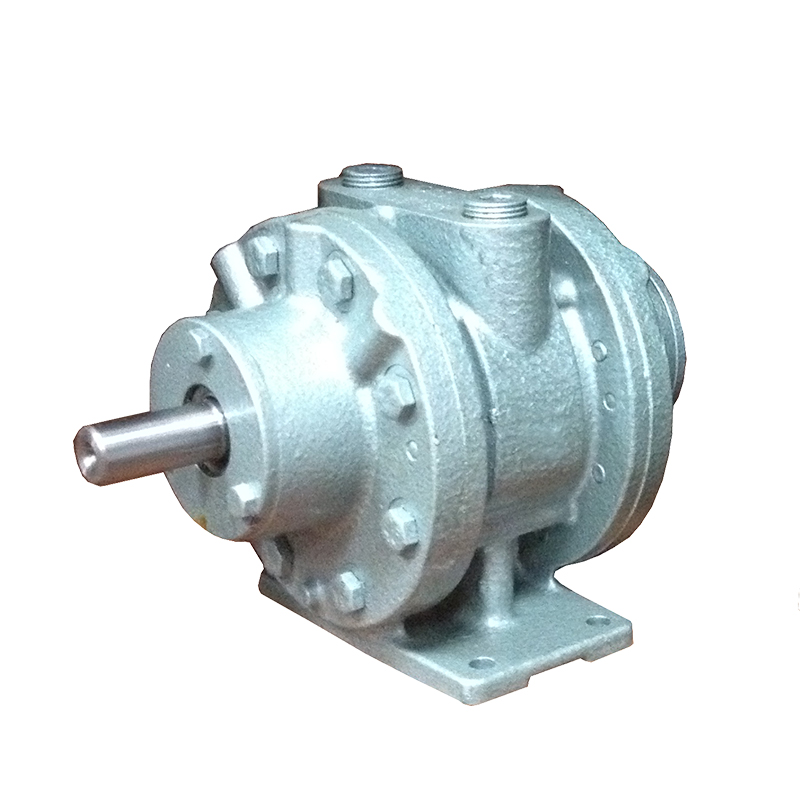

The pneumatic agitator's structural design adheres to the principles of simplicity and practicality. Its core components include the air motor, agitator shaft, impeller, and air filter and control unit. This modular layout makes installation and commissioning of the equipment simple and quick, allowing it to be quickly adapted to different production equipment layouts. The impeller offers a wide range of material options, including corrosion-resistant materials such as stainless steel and engineering plastics, depending on the chemical properties of the material, ensuring stability and durability when handling a wide range of materials.

Pneumatic agitators offer significant advantages in terms of maintenance. Since the equipment lacks a complex internal electrical system and has a relatively small number of parts, routine maintenance focuses on simple tasks such as cleaning the air filter and inspecting the seals. Even if a malfunction occurs, operation can be restored by quickly replacing modular components, significantly reducing downtime. This easy-to-maintain feature simplifies equipment management and minimizes production interruptions caused by improper maintenance, providing a reliable guarantee for improving production efficiency.

In the future, with the development of intelligent industry, pneumatic air driven mixers will evolve towards automated control. By integrating sensors and intelligent control systems, real-time monitoring and automatic adjustment of the mixing process will be achieved, further improving mixing accuracy and production efficiency. Furthermore, the use of new materials will enhance the equipment's performance under extreme operating conditions such as high temperature and high pressure resistance, expanding its application in emerging fields such as new energy and environmental protection. As a key piece of equipment in the industrial mixing field, pneumatic agitators will continue to be driven by technological innovation, providing superior solutions for efficient production across various industries.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى