Submit feedback

Pneumatic Piston Air Motors: A new favorite for efficient driving, an innovator of industrial equipment power systems

2025.07.01

2025.07.01

Industry News

Industry News

In the fields of industrial automation, mining, petrochemicals, and transportation equipment, Pneumatic Piston Air Motors are increasingly becoming an efficient and safe power choice. Compared with electric motors or hydraulic motors, pneumatic motors are favored by more and more manufacturers and engineers for their explosion safety, adaptability to the working environment, and excellent controllability.

Pneumatic Piston Air Motors is a power device that drives the piston to reciprocate through compressed air, thereby driving the output shaft to rotate. Its structure consists of a cylinder block, a piston, a crank-connecting rod mechanism, an intake and exhaust system, etc. During operation, compressed air alternately acts on both ends of the piston, and the linear reciprocating motion is converted into rotational motion through a mechanical conversion mechanism.

Compared with vane pneumatic motors, piston motors have higher starting torque and better energy efficiency, and are particularly suitable for low-speed and high-load applications.

Core advantages of Pneumatic Piston Air Motors

1. High starting torque and excellent low-speed performance

Due to its piston structure, pneumatic piston motors can output extremely high torque at the moment of starting, which is particularly suitable for industrial equipment that starts with load. For example, in high-load operating environments such as underground coal mines and drilling platforms, they perform better than vane motors and motors.

2. Fearless of harsh environments and high safety

Since pneumatic motors use compressed air as a power source, there is no electric spark and no risk of overheating, so they can be used in flammable and explosive or high-humidity and high-dust environments, such as paint shops, pharmaceutical workshops, chemical plants, tunnel construction, etc.

3. Flexible control and convenient reversal

The motor can be easily reversed by changing the air intake direction, and the control valve can be used to achieve stepless speed regulation. This feature is particularly useful in automated production lines that require frequent start-stop or direction switching.

4. Compact structure and convenient maintenance

The overall structure of the pneumatic motor is simple, with fewer parts, and it is more convenient to repair and maintain. At the same time, its small size and light weight make it more suitable for integration of space-constrained equipment.

Main application scenarios of Pneumatic Piston Air Motors

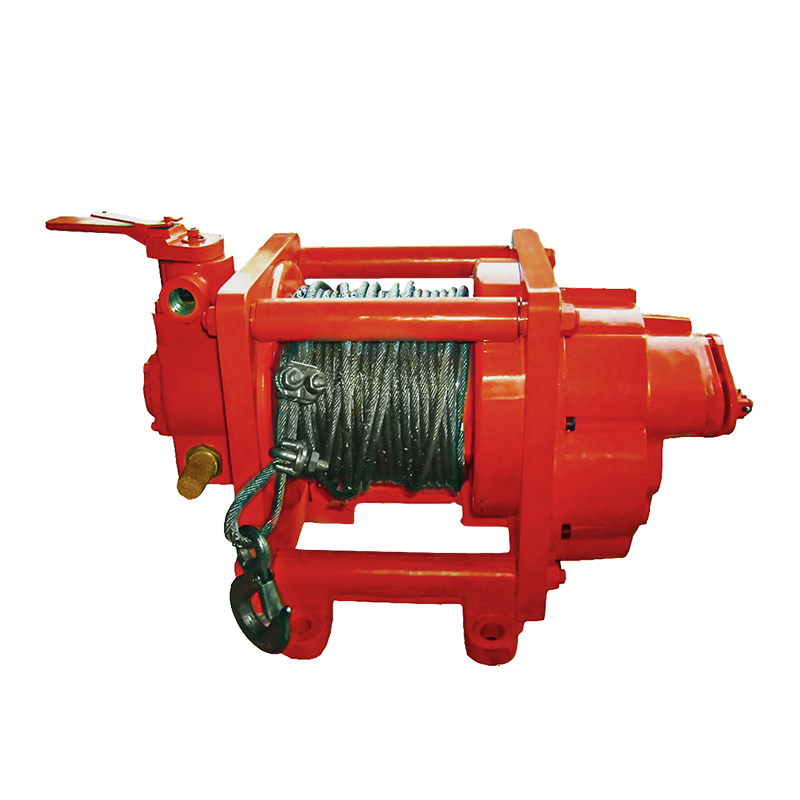

Oil and gas industry

Used in wellhead operation equipment, mud pump drive, drilling platform pipeline transportation equipment, etc., and can work stably in high explosion risk areas.

Chemical and pharmaceutical equipment

Applied to mixers, reactors, sealed mixer drives, etc., to provide lasting power in scenarios with extremely high environmental safety requirements.

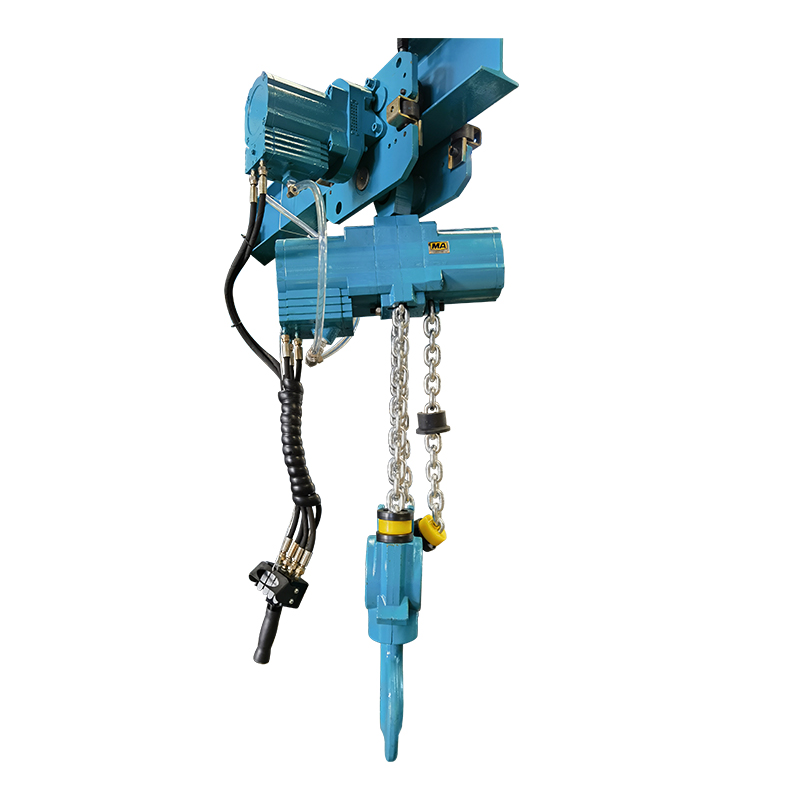

Mining and tunnel construction

In harsh environments such as underground coal mines and tunnel excavation, it is used to drive transport trolleys, lifting equipment and drainage pumps.

Ship and railway equipment

Suitable for ship deck machinery, train switch control devices and other occasions, replacing traditional motors to improve safety performance.

Food and packaging machinery

Thanks to the oil-free lubrication design, some piston motors can be used in food processing, packaging production lines and other applications with high cleanliness requirements.

How to correctly select a pneumatic piston motor?

Determine the working torque and speed: Piston motors are particularly suitable for low-speed and high-torque applications, and the load conditions must be clearly defined when selecting.

Evaluate the air source conditions: including air pressure (usually 0.4~0.8MPa), air source flow rate and gas cleanliness.

Frequency of use and continuous working time: The thermal stability and wear performance of the motor should be considered in situations with frequent start and stop.

Whether oil-free lubrication is required: Oil-free pneumatic motors must be selected in industries such as food and pharmaceuticals.

Environmental safety level requirements: If explosion-proof level certification (ATEX, etc.) is required, it should be specially indicated.

Pneumatic Piston Air Motors have become an ideal power solution for many industries under harsh working conditions due to its high torque, good safety, strong adaptability and many other advantages. In the future, with the continuous improvement of technology and the acceleration of intelligent integration, pneumatic motors will play a more important role and provide more efficient, environmentally friendly and intelligent power support for industrial equipment.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى