Submit feedback

About Us

The company has been committed to product innovation for many years, focusing on the updating and upgrading of pneumatic motors. With fine concepts and continuous investment, it has created a creative design team and has designed multiple innovative pneumatic products. Currently, it has independent intellectual property rights and has obtained more than 30 product patents.

The company's main products include pneumatic motors and a series of products such as pneumatic hoists, pneumatic winches, pneumatic mixers, pneumatic emulsifiers, pneumatic explosion-proof pumps, pneumatic mixers, pneumatic fans, and industrial automation equipment pneumatic control system engineering developed based on specific production needs.

The company strictly follows the ISO9001 quality management system for product design, production, assembly, and testing. With the efforts of all employees, the company has passed the ISO9001 international quality system certification. Through strict procedures and high standards of auditing, the company has successfully passed the recognition of a "national high-tech enterprise". Gaston Company is gradually moving towards internationalization with its own strength and a global perspective.

Users with different needs will always be the coordinates we strive for and the driving force for constantly surpassing ourselves and striving for innovation! Gaston Company looks forward to sincere cooperation with friends from all walks of life at home and abroad to create brilliance together!

Honor Certificate

Latest News

-

Industry News 2025-09-22

With the advancement of industrial automation technology, pneumatic pumps, as an efficient and relia...

View More -

Industry News 2025-09-15

In modern industry, pneumatic industrial fans have become indispensable equipment in many sectors du...

View More -

Industry News 2025-09-08

In modern industrial production systems, the performance of power units directly determines the effi...

View More -

Industry News 2025-09-01

In modern industry, the choice of power transmission equipment directly impacts production efficienc...

View More -

Industry News 2025-08-22

In the vast arena of modern industrial production, lifting equipment is an indispensable "behind-the...

View More

Contact Us Now

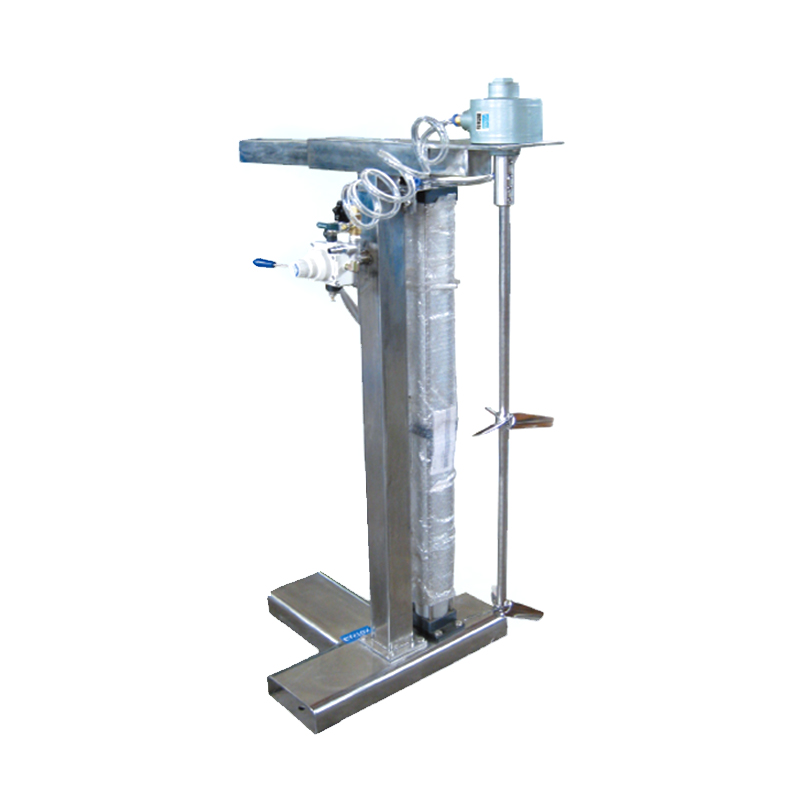

Single Column Pneumatic Mixer Industry knowledge

In view of the high-precision mixing needs of the pharmaceutical industry, how can the Single Column Pneumatic Mixer ensure mixing uniformity and meet the cleaning and aseptic requirements of GMP (Good Manufacturing Practice)?

In view of the high-precision mixing needs of the pharmaceutical industry, Single Column Pneumatic Mixer needs to take a series of measures to ensure mixing uniformity and meet the cleaning and aseptic requirements of GMP (Good Manufacturing Practice). The following are some specific practices and suggestions:

1. Ensure mixing uniformity

Optimize mixing design:

Agitator structure and speed: Design a reasonable agitator shape and blade angle, and match the appropriate speed to ensure that the materials can be fully mixed during the mixing process to achieve the required uniformity.

Mixing chamber design: Optimize the structure of the mixing chamber, such as using appropriate volume and shape to reduce dead corners and residues and improve mixing efficiency.

Precise control:

Pneumatic motor control: Use a precise pneumatic motor control system to achieve precise adjustment of the mixing speed to meet the mixing needs of different materials.

Mixing time control: According to the characteristics of the material and experimental data, set a reasonable mixing time to ensure that the mixing uniformity meets the requirements.

Monitoring and feedback:

Online monitoring system: Install an online monitoring system to monitor various parameters in the mixing process in real time, such as temperature, pressure, mixing time, etc., to ensure that the mixing process is stable and controllable.

Sampling and testing: Regularly sample and test the mixed materials, and verify whether the mixing uniformity meets the standards through laboratory analysis.

2. Meet the cleaning and sterility requirements of GMP

Equipment material selection:

Corrosion-resistant materials: Use corrosion-resistant materials that meet GMP requirements to manufacture agitators and mixing chambers, such as stainless steel, to avoid chemical reactions or contamination when materials come into contact with equipment.

Easy-to-clean design: Use structural designs that are easy to disassemble and clean, such as detachable agitators, smooth inner walls of mixing chambers, etc., to facilitate cleaning and disinfection.

Cleaning and disinfection:

Cleaning procedures: Develop detailed cleaning procedures, including the selection of cleaning agents, cleaning steps, cleaning time, etc., to ensure that the internal and external surfaces of the equipment are thoroughly cleaned without residue.

Disinfection: Use appropriate disinfection methods to disinfect the equipment, such as using disinfectants such as alcohol and quaternary ammonium salts, or combining physical disinfection methods such as ultraviolet rays and ozone to kill or remove microorganisms on the surface of the equipment.

Environmental control:

Clean room: Place the Single Column Pneumatic Mixer in a clean room that meets GMP requirements, and reduce interference from external pollution sources by controlling parameters such as indoor temperature, humidity, and air cleanliness.

Operation by personnel: Operators must undergo professional training and wear protective equipment such as clean clothes and gloves to reduce pollution to the equipment.

Verification and records:

Cleaning verification: Cleaning verification is performed regularly to ensure that the equipment cleanliness meets the requirements by simulating the cleaning operations in the actual production process and sampling to test the cleaning effect.

Record management: Establish a complete record management system, record the cleaning, disinfection, and maintenance processes of the equipment in detail and keep them properly for future reference.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى