Submit feedback

About Us

The company has been committed to product innovation for many years, focusing on the updating and upgrading of pneumatic motors. With fine concepts and continuous investment, it has created a creative design team and has designed multiple innovative pneumatic products. Currently, it has independent intellectual property rights and has obtained more than 30 product patents.

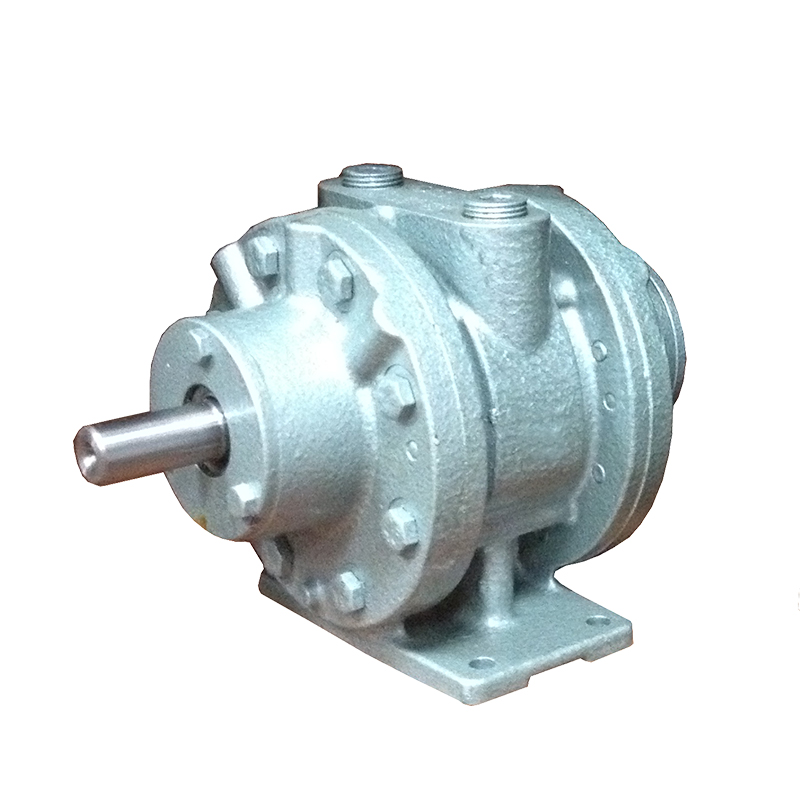

The company's main products include pneumatic motors and a series of products such as pneumatic hoists, pneumatic winches, pneumatic mixers, pneumatic emulsifiers, pneumatic explosion-proof pumps, pneumatic mixers, pneumatic fans, and industrial automation equipment pneumatic control system engineering developed based on specific production needs.

The company strictly follows the ISO9001 quality management system for product design, production, assembly, and testing. With the efforts of all employees, the company has passed the ISO9001 international quality system certification. Through strict procedures and high standards of auditing, the company has successfully passed the recognition of a "national high-tech enterprise". Gaston Company is gradually moving towards internationalization with its own strength and a global perspective.

Users with different needs will always be the coordinates we strive for and the driving force for constantly surpassing ourselves and striving for innovation! Gaston Company looks forward to sincere cooperation with friends from all walks of life at home and abroad to create brilliance together!

Honor Certificate

Latest News

-

Industry News 2025-09-22

With the advancement of industrial automation technology, pneumatic pumps, as an efficient and relia...

View More -

Industry News 2025-09-15

In modern industry, pneumatic industrial fans have become indispensable equipment in many sectors du...

View More -

Industry News 2025-09-08

In modern industrial production systems, the performance of power units directly determines the effi...

View More -

Industry News 2025-09-01

In modern industry, the choice of power transmission equipment directly impacts production efficienc...

View More -

Industry News 2025-08-22

In the vast arena of modern industrial production, lifting equipment is an indispensable "behind-the...

View More

Contact Us Now

Vane Pneumatic Motor Industry knowledge

During the design process, how to ensure that the compressed air can remain stable and efficient when flowing inside the vane air motor to reduce energy loss?

Anhui Gaston Precision Machinery Co., Ltd., as the industry's leading precision machinery manufacturer, we strictly follow the ISO9001 quality management system and deeply implant the concept of quality awareness and technological innovation from the beginning of product design. During the design process of the compressed air-driven vane air motor, we have taken a series of advanced measures to ensure that the airflow remains stable and efficient when flowing inside the motor, thereby significantly reducing energy loss and improving overall performance.

Design advantages and strategies:

Fluid dynamics optimization design: We use advanced fluid dynamics software (CFD) to conduct accurate simulations and analyze the flow state of compressed air inside the motor under different design parameters. By optimizing the blade shape, arrangement angle and flow channel design, the airflow path is ensured to be smooth and unobstructed, vortices and turbulence are reduced, thereby improving energy conversion efficiency.

Efficient sealing system: Designed and adopted high-precision, low-friction sealing elements to effectively prevent compressed air leakage and keep the internal pressure of the motor stable. This not only improves the utilization of compressed air, but also reduces energy waste due to leakage.

Intelligent speed regulation mechanism: Combined with advanced pressure and flow sensing technology, it realizes intelligent regulation of motor speed. By accurately controlling the air source pressure and flow, it is ensured that compressed air can enter the motor in an optimal state under different working conditions and maintain stable output performance.

Overload protection design: The innovatively designed overload protection mechanism can automatically adjust the working state or temporarily cut off the air source when the motor is overloaded to avoid damage to the motor itself. It also prevents the body temperature from rising abnormally and ensures long-term stable operation of the equipment.

Material selection and heat treatment: High-strength, wear-resistant high-quality materials are used to manufacture key components of the motor, and undergo strict heat treatment processes to improve the durability and fatigue resistance of the components. This not only extends the service life of the motor, but also ensures long-term unobstructed airflow channels.

Modular design: The modular design concept is adopted to facilitate customized adjustments according to customer needs, and also facilitates subsequent maintenance and repair. The modular structure makes it easy and fast to replace worn parts, further ensuring the efficient operation of the motor.

How does a vane-type pneumatic motor achieve self-protection in overload conditions without damaging the motor itself and preventing the body temperature from rising?

Anhui Gaston Precision Machinery Co., Ltd., as a leading domestic professional pneumatic motor and equipment manufacturer integrating design, research and development, production, sales and service, has one of its core advantages in its innovative vane-type pneumatic motor technology, which demonstrates excellent self-protection capabilities when dealing with overload conditions, effectively avoiding motor damage and abnormal body temperature rise.

Specifically, the vane-type pneumatic motor of Anhui Gaston Precision Machinery Co., Ltd. achieves self-protection through the following mechanisms when encountering overload conditions:

Intelligent pressure regulation system: The motor is equipped with a precise pressure sensing and regulation device that can monitor the pressure changes of the air source in real time. When the motor is subjected to a load exceeding its design, the system will automatically adjust the air intake or reduce the air source pressure to reduce the torque transmitted to the motor, thereby avoiding overload. This dynamic adjustment mechanism ensures that the motor can still operate stably under complex working conditions without being damaged by overload.

Efficient heat dissipation design: The optimized gap design between the motor blades and the cylinder body not only improves the energy conversion efficiency, but also enhances the heat dissipation performance. In the case of overload, even if part of the energy is converted into heat energy, the heat can be quickly dissipated through the carefully designed heat dissipation channel and efficient heat dissipation materials, keeping the motor body temperature within a safe range and preventing overheating.

Overload buffer mechanism: The vane-type pneumatic motor is also equipped with an overload buffer mechanism, which can absorb part of the impact energy when the motor is subjected to an abnormally large load, slow down the impact on the core components of the motor, and thus protect the motor from damage caused by instantaneous overload. This design enables the motor to maintain structural integrity and functional stability when facing sudden heavy loads or misoperation.

Intelligent monitoring and alarm system: Some high-end models of pneumatic motors are also equipped with an intelligent monitoring and alarm system that can monitor the operating status of the motor in real time, including key parameters such as load conditions, temperature, and pressure. Once an abnormality is detected, the system will immediately sound an alarm and may automatically take protective measures, such as cutting off the air source or reducing the speed, to ensure the safe operation of the motor.

The vane-type pneumatic motor of Anhui Gaston Precision Machinery Co., Ltd. has achieved excellent self-protection capabilities in overload conditions through comprehensive measures such as intelligent pressure regulation, efficient heat dissipation design, overload buffer mechanism, and intelligent monitoring and alarm system, effectively preventing motor damage and abnormal temperature increase of the body, providing users with a more reliable and safe pneumatic power solution.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى