Submit feedback

Pneumatic chain hoist: a high-efficiency solution in the field of industrial lifting

2025.07.08

2025.07.08

Industry News

Industry News

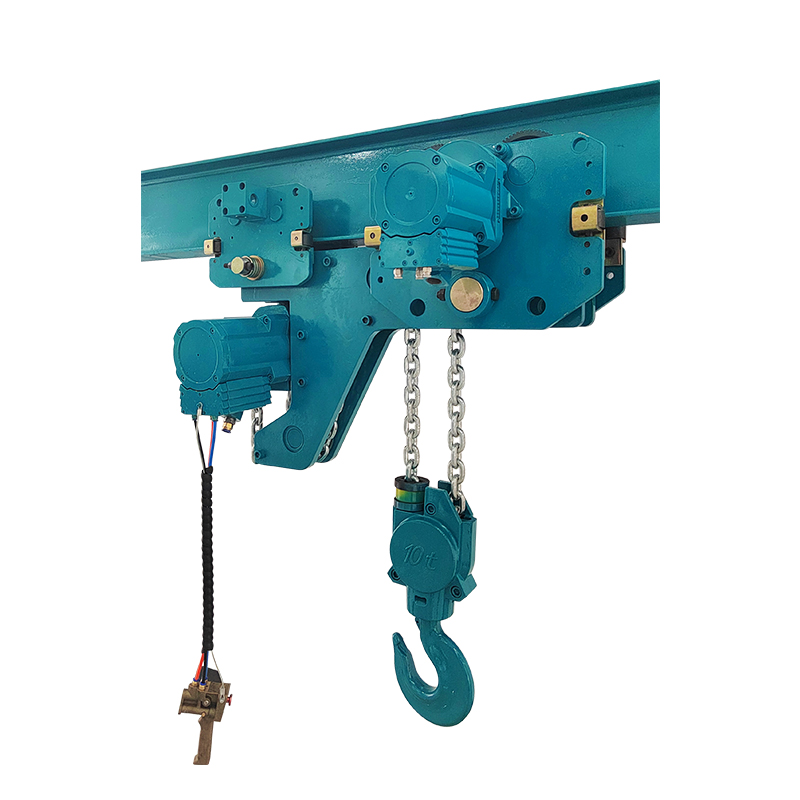

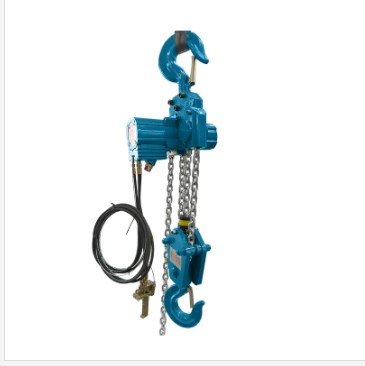

In modern industrial production, the performance of lifting equipment directly affects production efficiency and operational safety. As a lifting tool powered by compressed air, pneumatic chain hoists occupy an irreplaceable position in high-risk environments such as chemical, mining, and ships with their unique advantages.

1. Core advantages: Why pneumatic chain hoists are the first choice for high-risk environments

The core competitiveness of pneumatic chain hoists comes from their inherently safe design. Compared with electric hoists, it does not require electric drive, which eliminates the risk of explosion caused by electric sparks from the root, making it a standard equipment for flammable and explosive places such as oil and gas fields and paint shops.

In terms of environmental adaptability, pneumatic chain hoists show amazing toughness. Its fully sealed structure can operate stably at extreme temperatures of -20℃ to 80℃, and can maintain 98% of trouble-free working time even in mine tunnels where the dust concentration exceeds the standard by 10 times. This characteristic of "ignoring harsh environments" makes it an ideal choice for outdoor infrastructure and underground projects.

The precise controllability of power output is another highlight. By adjusting the air source valve, the operator can achieve stepless speed change from 0.1m/min to 10m/min, and when hoisting precision instruments, the positioning error can be controlled within the range of ±2mm.

II. Key technical parameters: How to measure equipment performance

The rated lifting capacity is the primary indicator for selection. Currently, the market products cover the range of 0.5t to 100t. The lifting height of the same model equipment under single-chain and double-chain configurations is significantly different. For example, the lifting height of a 5t-level hoist can reach 6m with a single chain, while the double chain is reduced to 3m. It needs to be flexibly selected according to the working space.

The working level (ISO M3-M8) directly determines the life of the equipment. The M5-level hoist is suitable for intermittent operations, while the M8-level can withstand 24-hour continuous operation.

3. Typical application scenarios: cross-border performance from workshop to deep sea

In the field of shipbuilding, pneumatic chain hoists solve the explosion-proof problem of welding workshops.

In deep-sea salvage, special anti-corrosion pneumatic hoists show extraordinary strength. In salvage operations at a depth of 300 meters, its titanium alloy chain can withstand an impact tension of 3 times the rated load, and with the underwater special air source device, it has successfully completed the recovery of the wreckage of a sunken submarine.

In the food and pharmaceutical industry, pneumatic hoists made of stainless steel meet the requirements of GMP certification.

4. Selection and maintenance: a practical guide to extend the life of equipment

When selecting, the principle of "working condition matching" should be followed: models with air filtration devices should be preferred in dusty environments; in humid environments, it is necessary to confirm that the protection level reaches IP65 or above; and buffer-type pneumatic motors should be equipped for frequent reversing operations.

The key to daily maintenance lies in air source treatment. It is recommended to replace the oil-water separator filter element every 100 working hours and spray the chain with special lubricating oil every month.

With the advancement of Industry 4.0, intelligent pneumatic chain hoists have remote diagnostic functions. By adding pressure sensors and IoT modules, parameters such as air source pressure and chain tension can be monitored in real time to warn of potential failures in advance. This "predictive maintenance" model is rewriting the traditional equipment management logic.

The technological evolution of pneumatic chain hoists has always revolved around the two cores of safety and efficiency. In the future, with the advancement of materials science, the application of carbon fiber chains may reduce the weight of equipment, and the popularization of servo pneumatic technology will further improve control accuracy. For industrial producers, a deep understanding of the characteristics of this type of special lifting equipment is not only a prerequisite for ensuring production safety, but also the key to improving competitiveness.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى