Submit feedback

About Us

The company has been committed to product innovation for many years, focusing on the updating and upgrading of pneumatic motors. With fine concepts and continuous investment, it has created a creative design team and has designed multiple innovative pneumatic products. Currently, it has independent intellectual property rights and has obtained more than 30 product patents.

The company's main products include pneumatic motors and a series of products such as pneumatic hoists, pneumatic winches, pneumatic mixers, pneumatic emulsifiers, pneumatic explosion-proof pumps, pneumatic mixers, pneumatic fans, and industrial automation equipment pneumatic control system engineering developed based on specific production needs.

The company strictly follows the ISO9001 quality management system for product design, production, assembly, and testing. With the efforts of all employees, the company has passed the ISO9001 international quality system certification. Through strict procedures and high standards of auditing, the company has successfully passed the recognition of a "national high-tech enterprise". Gaston Company is gradually moving towards internationalization with its own strength and a global perspective.

Users with different needs will always be the coordinates we strive for and the driving force for constantly surpassing ourselves and striving for innovation! Gaston Company looks forward to sincere cooperation with friends from all walks of life at home and abroad to create brilliance together!

Honor Certificate

Latest News

-

Industry News 2025-09-22

With the advancement of industrial automation technology, pneumatic pumps, as an efficient and relia...

View More -

Industry News 2025-09-15

In modern industry, pneumatic industrial fans have become indispensable equipment in many sectors du...

View More -

Industry News 2025-09-08

In modern industrial production systems, the performance of power units directly determines the effi...

View More -

Industry News 2025-09-01

In modern industry, the choice of power transmission equipment directly impacts production efficienc...

View More -

Industry News 2025-08-22

In the vast arena of modern industrial production, lifting equipment is an indispensable "behind-the...

View More

Contact Us Now

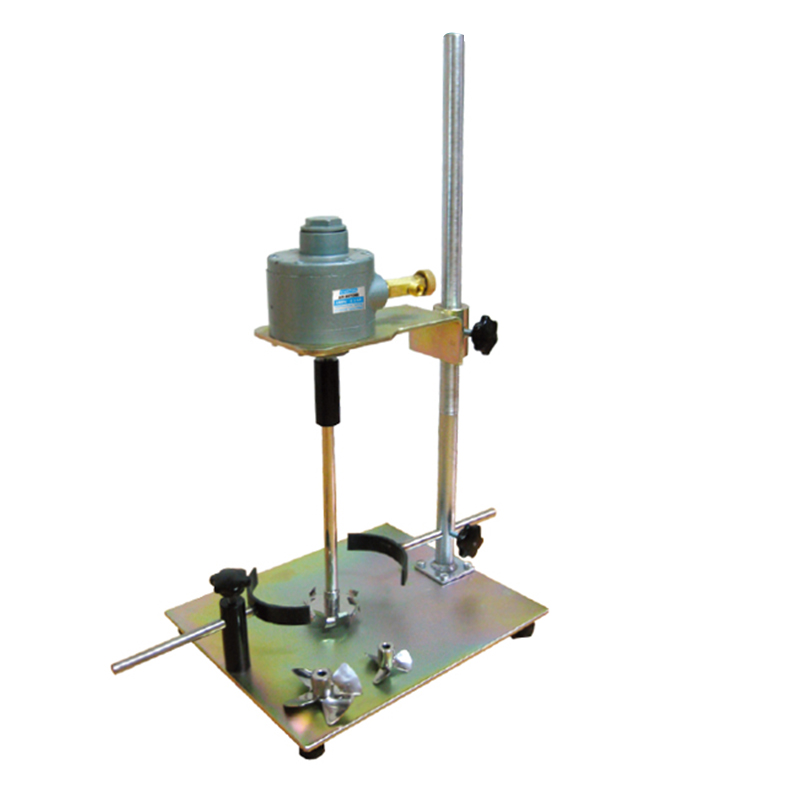

Laboratory Small Pneumatic Mixer Industry knowledge

In a laboratory environment, what are the unique advantages of Laboratory Small Pneumatic Mixer compared to traditional electric mixers, especially when special conditions such as explosion-proof, dust-free or high temperature are required?

In a laboratory environment, Laboratory Small Pneumatic Mixer has a series of unique advantages over traditional electric mixers, especially under special conditions such as explosion-proof, dust-free or high temperature. Here is a detailed analysis of these advantages:

1. Explosion-proof performance

The essential advantages of pneumatic stirrers: Pneumatic stirrers use compressed air as a power source, so they are inherently less prone to sparks or high temperatures, which is especially important in laboratory environments that require explosion protection. In industries such as chemistry, medicine, oil and gas, laboratories often handle flammable and explosive substances, and electric mixers may cause sparks due to electrical faults, causing accidents. Pneumatic agitators significantly reduce this risk.

Improved safety: In explosion-proof areas, the use of pneumatic mixers can ensure the safety of the experimental process and protect experimental personnel and equipment from explosion threats.

2. Adaptability to dust-free environment

Reduce dust generation: The pneumatic mixer does not produce electromagnetic radiation and electromagnetic interference during its working process, and its working principle also reduces the generation of dust. This is particularly important in laboratories that need to maintain a dust-free environment, such as semiconductor manufacturing and precision instrument testing.

Easy to clean and maintain: Because pneumatic mixers are simple in structure and generally do not contain complex electrical components, they are easier to clean and maintain, helping to keep the laboratory tidy and sterile.

3. High temperature environment adaptability

High temperature resistance: In some high-temperature experimental environments, the electric mixer may not work properly or even be damaged due to excessive temperature. Due to its unique power source and working principle, pneumatic agitators usually have better high temperature resistance and can work stably under high temperature conditions.

Reduce heat accumulation: The pneumatic stirrer generates relatively little heat during work and is easily discharged through the cooling system, thereby reducing the accumulation of heat in the laboratory and helping to maintain the stability of the experimental environment.

4. Flexibility and reliability

Flexible power source: Pneumatic mixers do not rely on power supply, so they can work normally in environments where power is unstable or unavailable. This makes them more flexible in laboratories in certain remote areas or under special conditions.

High reliability: Pneumatic agitators generally have high reliability due to their simple structure and robustness. It can maintain stable performance output even under long-term continuous operation or high-load operation.

For experiments that require precise control of mixing speed and time-sensitive experiments, how can Laboratory Small Pneumatic Mixer achieve high-precision speed regulation and automated control to improve the accuracy of experimental results?

For experiments that require precise control of mixing speed and time-sensitive experiments, Laboratory Small Pneumatic Mixer (laboratory small pneumatic mixer) usually relies on its advanced design, precise adjustment mechanism and possible intelligent control system to achieve high-precision speed regulation and automated control. Although the specific technical details may vary from manufacturer to manufacturer and product model to model, here are some general methods and principles:

1. Precision flow control valve

Working principle: The speed of the pneumatic agitator is usually directly related to the supplied air pressure and flow. Through the precision flow control valve, the compressed air flow entering the agitator can be precisely adjusted to achieve precise control of the stirring speed.

Adjustment accuracy: Modern flow control valves usually use electronic or mechanical adjustment mechanisms, which can achieve high-precision flow control and ensure the accuracy and stability of the stirring speed.

2. Intelligent control system

Integrated control unit: Some high-end pneumatic stirrers may be equipped with an intelligent control unit that can receive instructions from the laboratory automation system and automatically adjust the stirring speed according to the instructions.

Programming and setting: Users can program and set parameters such as stirring speed and time through the control panel or computer interface, and the control system will automatically execute the set program to ensure the accuracy and repeatability of the experiment.

3. Sensors and feedback mechanism

Speed sensor: Some pneumatic stirrers may have built-in speed senso

rs to monitor the stirring speed in real time and feed back the data to the control system.

Closed-loop control: The control system compares the feedback data with the set value, and realizes closed-loop control of the stirring speed by adjusting the actuators such as the flow control valve to ensure the accuracy and stability of the stirring speed.

4. Automation integration

Integration with laboratory automation system: Pneumatic stirrers can be easily integrated with laboratory automation systems (such as LIMS, automated workstations, etc.) to achieve automation and intelligent management of experimental processes.

Remote control: Through the remote control system, users can monitor and operate the stirrer outside the laboratory to improve the convenience and efficiency of the experiment.

5. Factory customization service

Special needs customization: For experiments with special needs, users can communicate with us to customize pneumatic agitators with specific speed adjustment range and accuracy.

Technical support: We usually provide comprehensive technical support and after-sales service to help users solve problems encountered during use.

English

English русский

русский Français

Français Español

Español 中文简体

中文简体 عربى

عربى